Circular Economy for the Chemical Processing Industry

November 2021

/Category:General

An increase in the global population, as well as increased growth seen by industries and economies, has placed ever greater pressure on the material and energy resources of the world. For example, as more people use and throw away mobile devices, more and more metals (such as in cell phone batteries) end up in landfills.

This use-and-discard model of resource utilization is negatively affecting human and environmental health. In fact, this model involves high energy and water consumption, emissions of toxic substances, and disruption of natural assets such as geology, soil, and water. Also, it is no secret that supply chains have been negatively impacted during COVID, and one can imagine how a linear model like the one described above could be part of exacerbating, rather than alleviating, the problem.

Evidently, there is a need for a circular economy that employs a novel supply chain model, which is both regenerative and environmentally conscious. A circular economy would increase resource efficiency by looping material and energy resources through the product life cycle. By doing so, this results in benefits such as reduced waste generation, increased economic efficiency, social sustainability, and technological advances.

What Is a Circular Economy?

Although the concept of a circular economy cannot be traced back to a single origin, it gained traction during the 1970s due to the surge of environmentalism at the time.

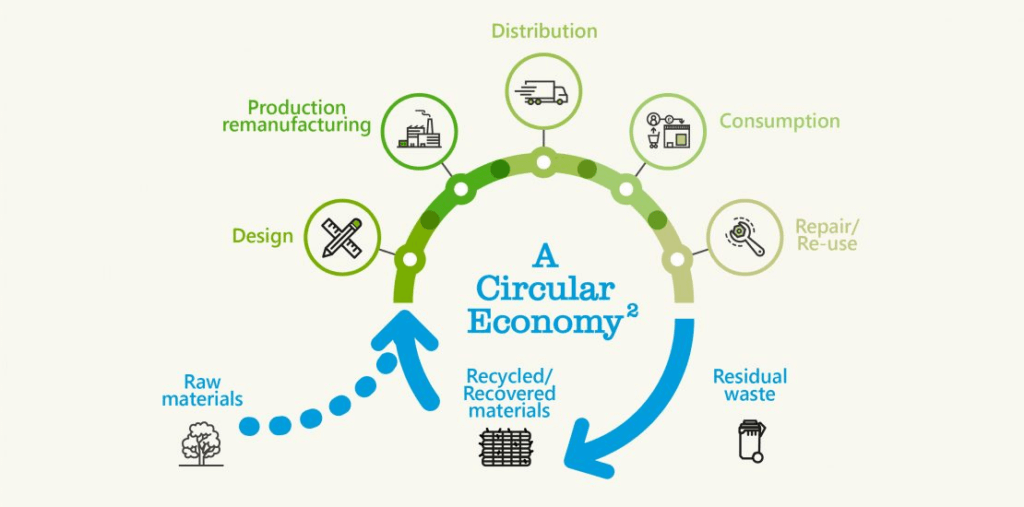

A circular economy consists of the cycling of resources and products. As with linear economies, a key step in the model is the extraction of raw materials from the earth, followed by the manufacture of products for sale or use. Unlike in a linear economy, instead of disposing of these products - and drawing more virgin resources from the earth - products are recycled and reused. One can either remake the same product or make completely different ones, forsysn example, turning used water bottles back into water bottles or into t-shirts.In a circular economy, resources are treated as finite, waste and pollution do not exist by design, and products and resources are kept in circulation.

Figure 1. In a circular economy, end-of-life products are recycled and recovered instead of becoming residual waste. (https://www.triumvirate.com/blog/do-you-know-about-the-circular-economy)

The Three Levels of Circular Economies

There are three levels at which the term circular economy is defined. First, at the micro-level (as embodied by products, companies, consumers); next at the meso-level (industrial symbiosis - wherein one industry’s byproducts become another industry’s raw materials); and finally at the macro-level (city, region, nation and beyond). In sync, these attempts at circularity increase environmental health, economic prosperity and social equity, in order to benefit current and future generations.5 Koch Modular participates at the micro-level, specifically by accelerating the pathway to commercialization for circular economy projects.

Lastly, the implementation of a circular economy plays a key role in the execution of the United Nations Sustainable Development Goals.7 According to the United Nations, a circular economy influences several SDGs, namely 6 on energy, 8 on economic growth, 11 on sustainable cities, 12 on sustainable consumption and production, 13 on climate change, 14 on oceans, and 15 on life on land.7 In other words, there is a significant driving force to adopt the principles of circular economy, not just from consumers but also from NGOs and governments.

Industries That Participate In a Circular Economy

Many industries already play a role or have the opportunity to play a role in the shift to circularity. An industry may choose to participate in more than one way; three ways are defined by the Ellen MacArthur Foundation, a charity promoting circular economy. They are:8

- Designing an economy and industry that reduces waste and pollution,

- Giving products more than one life cycle,

- Building the economy back to a more natural and sustainable place.

The chemical and pharmaceutical industries both take part in waning out wasted materials and reducing overall pollution. In the process of creating end products, these industries recycle the byproducts of filtration, distillation, and reaction steps in other stages of the system. Using the example of water, companies may either recycle treated water back into the beginning of the process, reuse it for heating or cooling, or dispose of it appropriately, after treatment. The linear methodology, on the other hand, would entail direct disposal without treatment or reuse.

The plastics industry is well-suited to give products more than one life cycle. In order to do this, plastics industry stakeholders must create a market for recycled materials, improve recycling rates, and innovate recycling technology. One such stakeholder example is Koch Modular’s client PureCycle. PureCycle produces ultra-pure recycled polypropylene and installs plants to perform the chemical conversion of waste feedstock to virgin-quality beads. The waste in this case is used carpet fibers and chip bag film. Koch Modular’s role was to design, build, and optimize a demonstration and commercial scale process to remove color, odor, and other contaminants.

Finally, the food and fertilizer industries - leaders in carbon emissions - are addressing the objective of building the economy and earth back to a more natural and sustainable place. These industries can adopt circular processes by incorporating sustainable food growth (i.e. microalgal-based food production that would avoid land clearing and exorbitant use of chemicals), utilizing plant-based fertilizers, and disposing of byproducts more responsibly. Koch Modular works with clients, who have biological processes or biological feedstocks, on optimizing yield and purification of their saleable products.

Long-Term Commitment To a Circular Economy

The circularization of the economy is a relevant and long-lasting trend that both individuals and businesses are buying into because of its environmental, economic, and equitable benefits. This trend is shaping industries that touch every aspect of human life including pharmaceuticals, food, materials, and energy. With the ongoing and emerging challenges that arise during its implementation, it is imperative that industries and individuals continue to educate and upskill themselves in the principles and solutions of the circular economy.

Contact us today or learn more at https://kochmodular.com/.

References

- Ibrahim, A.-J.; Shirazi, N. S. Energy-Water-Environment Nexus and the Transition Towards a Circular Economy: The Case of Qatar. Circ. Econ. Sustain. 2021. https://doi.org/10.1007/s43615-021-00037-w.

- What Are the Disadvantages of the Current Linear Economy? Kenniskaarten - het Groene Brein.

- Circular Economy Systems Engineering: A Case Study on the Coffee Supply Chain https://www.aiche.org/academy/videos/conference-presentations/circular-economy-systems-engineering-case-study-on-coffee-supply-chain (accessed 2021 -07 -07).

- Circular Economy Schools Of Thought https://www.ellenmacarthurfoundation.org/circular-economy/concept/schools-of-thought (accessed 2021 -07 -08).

- Avraamidou, S.; Baratsas, S. G.; Tian, Y.; Pistikopoulos, E. N. Circular Economy - A Challenge and an Opportunity for Process Systems Engineering. Comput. Chem. Eng. 2020, 133, 106629. https://doi.org/10.1016/j.compchemeng.2019.106629.

- Waymore https://waymore.world/ (accessed 2021 -07 -09).

- Droege, H.; Raggi, A.; Ramos, T. B. Overcoming Current Challenges for Circular Economy Assessment Implementation in Public Sector Organisations. Sustainability 2021, 13 (3), 1182. https://doi.org/10.3390/su13031182.

- What is a Circular Economy? | Ellen MacArthur Foundation https://www.ellenmacarthurfoundation.org/circular-economy/concept (accessed 2021 -07 -08).

But Today’s So-Called Trends In The CPI Seem to Have Staying Power.

As Koch Modular continues to partner with a range of startups, we have noticed a few trends among these fast-growing companies.

Source Local: Not Just for Your Farmers Market

When we think about the holidays, we rejoice in the celebrations not only at home but also with our work families. Whether it’s a holiday party, luncheon, or charitable event, it is a special time of year where we are able to work together and celebrate together.

Since we spend so much time at work, finding connections between our life as “real people”, and our work life is always an unexpected boon. Work/life balance means a lot of things and recently we noticed that a Buy Local trend, seen so clearly whenever we visit a farm-to-table restaurant, is also taking shape in the CPI industry. While you shopped at the local farmer stand for your corn this past summer, were you aware that the CPI industry was busy working on finding local sourcing for certain key chemicals? Sourcing chemicals locally allows businesses to save on transportation costs and avoid possible delivery interruptions. Koch

Modular is leading some of this effort, to minimize long transportation pipeline routes and find ways to use locally sourced, lower-cost materials. Recently, Koch worked together with New Jersey-based start-up Primus Green Energy on their natural gas to liquids technology, specifically their processes for converting natural gas to drop in gasoline and

methanol via reforming, reaction, and distillation unit operations. The technology focuses on regional production, providing in-basin demand and leveraging low-cost natural gas in areas such as the Marcellus and Permian Basins. Koch Modular assisted Primus with engineering services supporting the process conceptualization and pilot testing phase, followed by the development of the process design package, as well as the forthcoming detailed engineering and construction of their first commercial-scale system.

Industrial Biotech Startups Reaching Out

While not as close to home as the buying local trend, helping bring bio-based chemicals into the world makes us feel environmentally energized. We have seen an increase in the number of industrial biochemical startups (using feedstock with bio-based chemicals) coming to our door for help in moving towards full-scale production. Beyond our expertise in separations technologies and modular construction lay a natural affinity for helping start-ups analyze their path forward towards scale-up. Now that we’ve owned up to how talented we are (tongue in cheek), we realize that this type of consultative work has always been a part of our culture. Today, we work with industrial biotechs to help develop full-scale processes to manufacture their bio-based chemicals. This holiday season, whether you’re staying local or not, we hope that you revel in the joy and beauty of celebrating your connections with family and friends. As we assist our partners with establishing resources and aiding start-ups with appropriate next steps, we continue to work together and celebrate successful projects. From pilot testing to scale-up production, leveraging regional production to new biochemical production, our ModularLaunchTM process supports all of our clients. We wish you the Happiest of Holidays!