Industrial Distillation and Design in Chemical Engineering

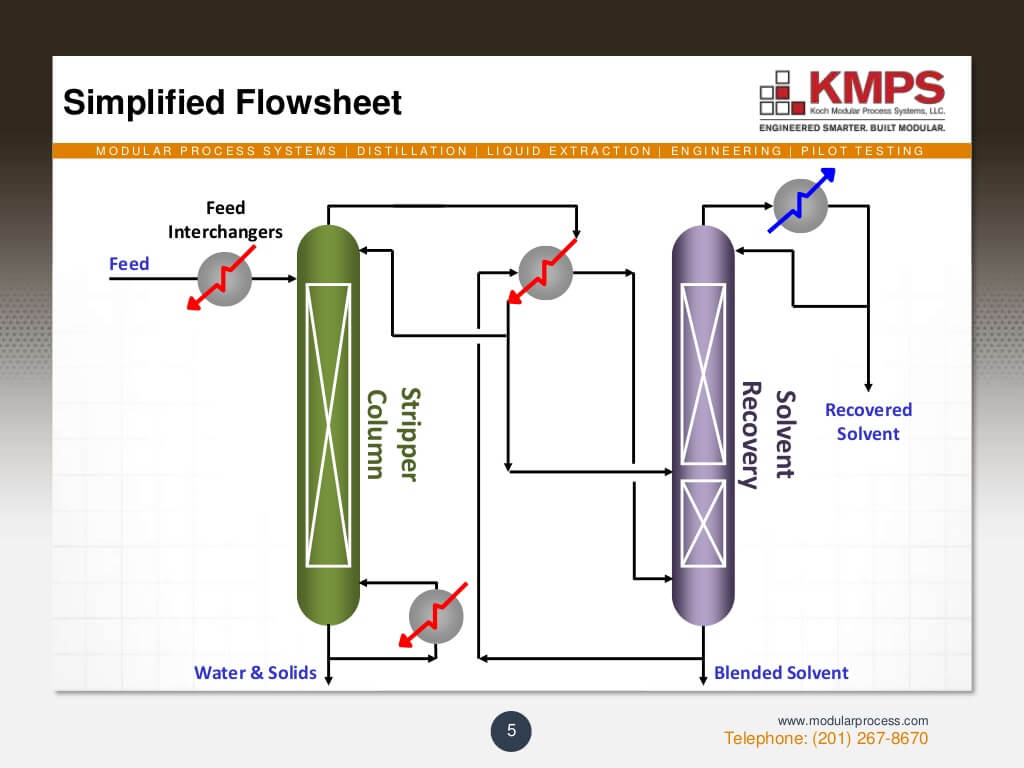

Distillation is the process of separating components of a liquid mixture by differences in boiling point or volatility. In chemical engineering and industrial applications, distillation has a universally important role in a wide range of applications for purified products, solvent recovery, and green technologies. Common forms of industrial-scale distillation include steam distillation, fractional distillation, vacuum, azeotropic, and extractive distillation.

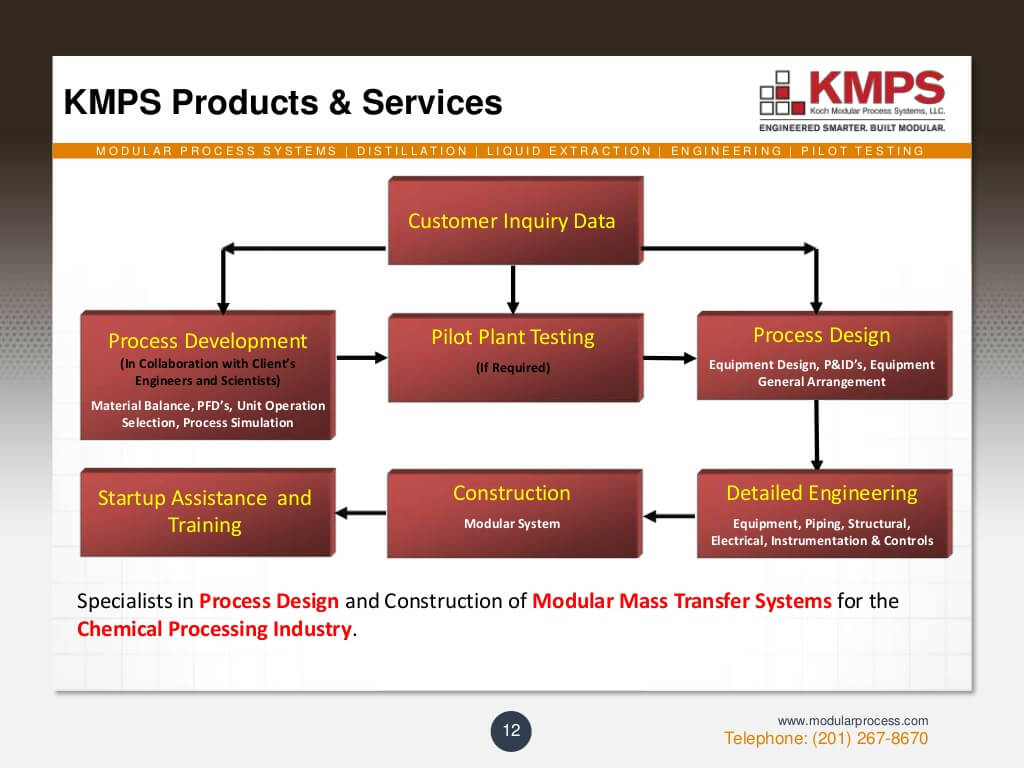

Koch Modular engineers excel at tackling and solving the toughest separation problems. Non-ideal mixtures are “run of the mill” challenges for us, where our years of experience make a difference in finding the best process solution.

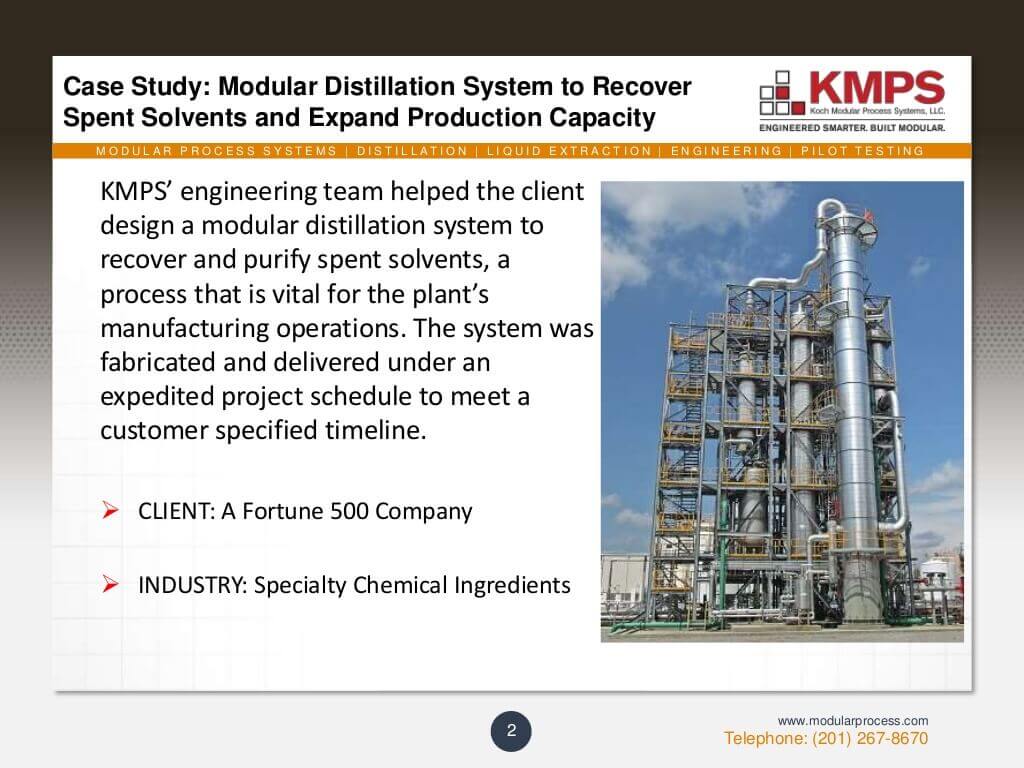

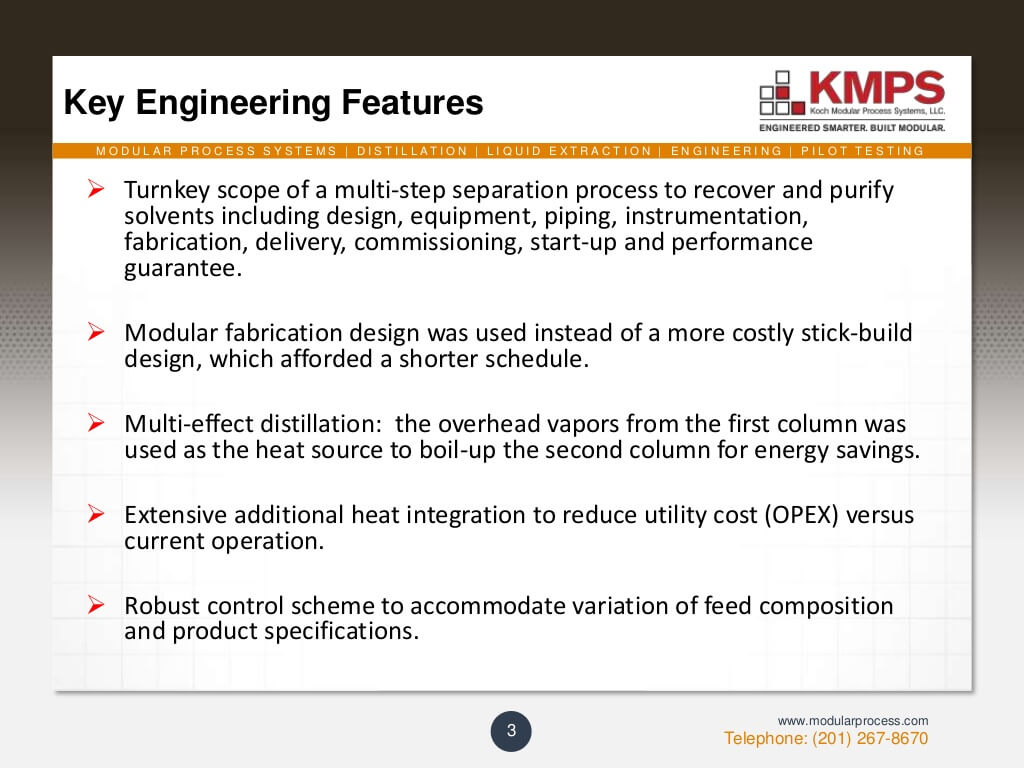

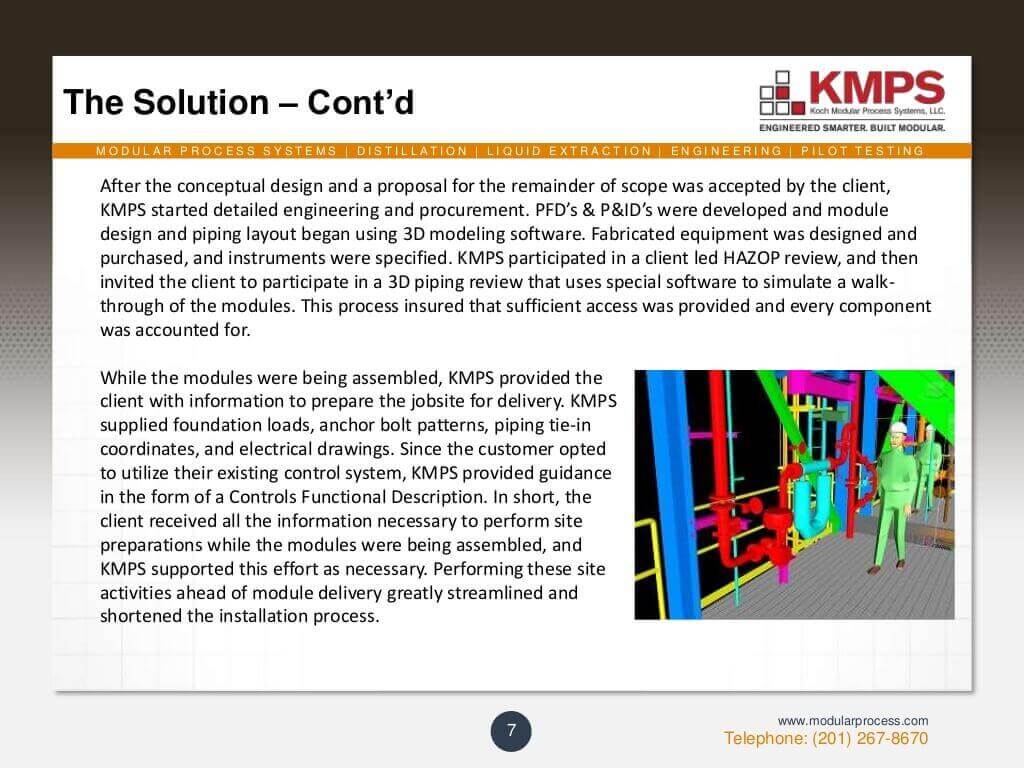

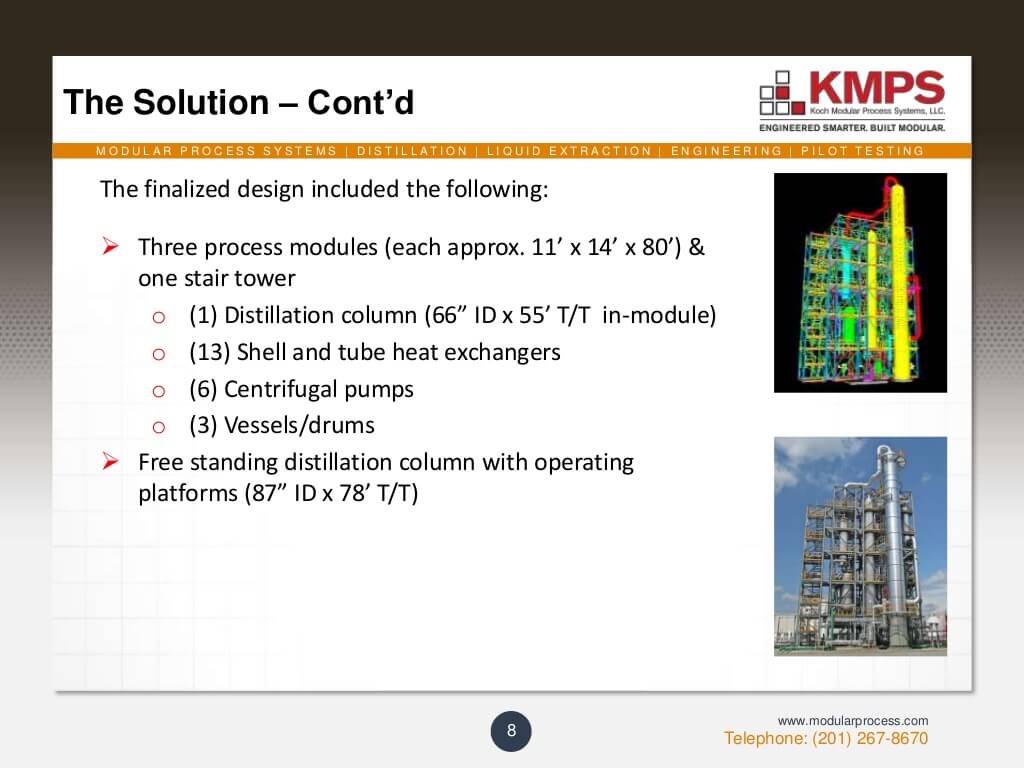

Koch Modular was able to develop a modular solvent recovery system design that significantly reduced energy consumption while increasing the client’s operational capacity by up to 40%.

For more successful case studies by Koch Modular, visit our Whitepapers and Presentations.

Koch Modular’s Distillation Expertise

Expand the following to learn more about the various ways Koch Modular’s engineers can help your industry. Browse between distillation applications, operation types, distillation types and column designs, as well as construction materials used and other distillation equipment.

Distillation Applications

Koch Modular’s process systems are designed for various industries, including pharmaceuticals, alternative energy sources, and wastewater cleanup. Koch Modular’s common applications include:

Operation Types

Koch Modular’s engineers design distillation operations around the separation needs of a client and the specific mixtures involved. Variables include the relative volatility of a mixture and the boiling points of each component. Common operation types utilized by Koch Modular include:

-

Continuous Distillation

-

Batch Distillation

-

Vacuum Distillation

-

Pressure Distillation

Distillation Types

We have decades of hands-on experience and distillation operation refinements to achieve optimal system efficiencies for the following distillation types:

-

Ideal and Non-Ideal Systems

-

Binary and Multi-Component Separations

Koch Modular also specializes in distillation techniques for the following processes:

-

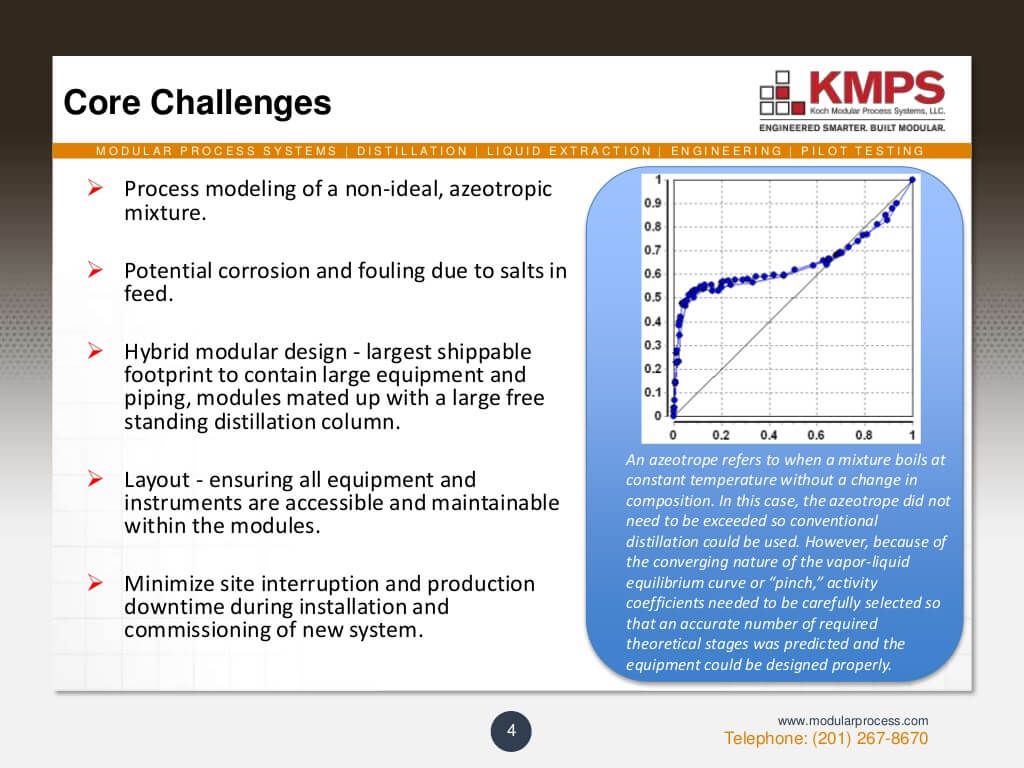

Azeotropic

-

Extractive

-

Reactive

-

Pressure Swing

Distillation Columns

Koch Modular has various distillation columns to choose from. They are designed for various process, energy, and cost efficiencies. Your options include:

-

Sieve and Valve Trays (e.g., high performance valves)

-

Structured Packings Columns

-

Dumped Packings Columns

Distillation Construction Materials

Distillation construction materials utilized for chemical engineering require the utmost performance in safety, reliability, durability and cost efficiency. To meet industry standards, Koch Modular utilizes the following materials for distillation systems:

-

Stainless and carbon steels, including nickel, Monel®, and Inconel alloys

-

Hastelloys, including chloride resistance alloys, AL6XN, and Alloy 2205 & 2507

-

Glass lined steel

-

Teflon lined steel

Additional exotic alloys are available depending on the project. Please inquire for more details.

Other Distillation Equipment

Shell & tube heat exchangers

-

Full thermal design and ratings

-

Condensers, reboilers, interchangers, vaporizers, etc.

Specialty design heat exchangers

-

Falling film reboilers

-

Low-pressure drop condensers

-

Reactors

-

Vapor/liquid separators

-

Liquid/liquid separators

-

Liquid/liquid contactors (extraction columns)

Frequently Asked Questions

Distillation is a separation technique that utilizes differences in boiling points between two or more chemical substances in their liquid phase. For example, methanol and water can be separated using distillation since the boiling point of methanol is around 65 °C and the boiling point of water is 100 °C.

Distillation as a separation technique, is used when there is a boiling point difference between two or more chemicals; however, if the boiling point difference is very large, it is possible to make a simple evaporator work. Generally, the chemicals in consideration for a distillation solution, tend to be miscible, hence decantation or physical separation is unfeasible; decanting is used to separate two immiscible liquids with different densities.

Alternatively, liquid-liquid extraction (LLE) is used to make separations feasible that are not practical to make via distillation, such as the removal of high boiling organic compounds from dilute aqueous streams or removal of acids/bases and salts from organic compounds (to learn more about LLE, click here – https://kochmodular.com/liquid-liquid-extraction/).

Lastly, filtration is used when there are solid particles of different sizes that can be separated by passing the mixture through a selective screen.

Liquid chromatography is another separation technique that is used in the chemical processing industry. Koch Modular focuses on the techniques described above, but we welcome discussion around any complex mass transfer problem.

A distillation column utilizes mass-transfer technology to affect a separation between components of interest. Distillation, as mentioned above, is the separation of chemicals based on a difference in their boiling points. As such, a distillation column requires energy to heat the mixture to a boil and then vaporize the lighter-boiling component, as well as a heat sink to condense the light component when it reaches the desired purity.

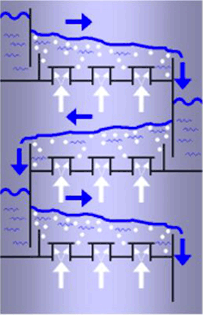

Distillation columns also utilize special internal equipment to help improve separation by providing lots of surface area for efficient contact of the liquid and vapor phases, and thus, efficient mass transfer. The two types of internals commonly in use are trays and packing. There are many types of each, all of which you can read more about on Koch-Glitsch’s website – https://koch-glitsch.com/products-overview. See below for a short summary of when we use trays versus when we use packing.

Packing are often the preferred choice of internals in a distillation column for two reasons. They allow for the most surface area per volume to effect mass transfer and they lead to very low pressure drops during normal operation. Additionally, whenever a client has a need for deep vacuum service, the use of packing can ensure that operating temperatures and pressures remain low. Packing tend also to be a better choice for systems with inclination to foam during distillation, where trays might plug up. Finally, packed internals can often result in smaller sized (lower diameter and height) columns versus tray internals, making them the preferred option to fit within our road-transportable module dimensions.

As column diameters get larger, and although there is no limit to the diameter of columns that can be packed, there is a point at which trays become the more economic option. Primarily, however, trays are used when packing have a high chance of fouling or plugging up. This is true for mixtures that have solid particles in them that can’t be removed upstream or in cases where precipitation of solids is likely during distillation. Trays are more reliable in fouling service and are more easily maintained and/or cleaned.

Koch Modular has long-standing partnerships with qualified column and vessel manufacturers, primarily in North America, who fabricate distillation columns and install structured packing or trays. With many years of experience, Koch Modular’s quality assurance team makes sure that equipment fabricators are held to high standards.

Typically, the time required to design and manufacture a distillation column is 4-5 months, depending in part on the size of the column and the materials of construction required. Our columns are generally provided within a steel frame and with surrounding equipment and piping, making project delivery timelines longer than the 4–5-month timeframe.

Most commonly, distillation columns are made from stainless or carbon steel. However, more exotic materials, such as plastics, ceramic, graphite, glass-lining, or higher metal alloys could be used depending on the corrosive and reactive properties of the chemical mixture.

The first step is the development of the process design for the column. This is generally done by modeling the separation using a process simulator such as ASPEN. The output of the process simulation provides the designer with the necessary information (tray by tray vapor and liquid flowrates, physical properties, operating temperatures and pressures, and number of stages) to select the proper size equipment and internals.

Next, column outline drawings are generated during the design phase which are used to guide the fabrication process. These outline drawings will provide the dimensions of the column, the details of the column internals, nozzles required, materials of construction, design temperatures and pressures, etc. The fabrication shop will then perform the mechanical design and create vessel fabrication drawings.

Then fabrication is ready to begin. The shell of the column can be made from rolled plate sections that are then welded together (or use a pipe shell if the column diameter is less than 24 inches) and build up the external structure of the column. Heads, nozzles, and other column attachments are then added onto the column shell. The column is then cleaned and pressure tested. Lastly, the column internals are installed and the column is installed into a modular frame (if possible) and properly insulated.

The reboiler and condenser are key to the successful operation of a distillation column. The reboiler is the main source of heat for vaporization and is typically located beside the sump of the column or below the column, depending on the type of reboiler. The condenser receives the overhead vapors from the column and condenses all or a portion of them. A fraction of the condensed distillate is normally fed back to the top of the column as reflux. Other ancillary pieces of equipment that accompany the distillation column include a reflux drum, feed filters, sidedraw or bottoms coolers, feed preheaters and economizers.

Distillation is ultimately a fairly broad term that can be used to describe anything that involves separation of chemical components based on their boiling points. However, there are a many other techniques that can be used in distillation. Examples include extractive distillation, azeotropic distillation, pressure-swing distillation, or vacuum distillation.