This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Solvent Recovery and Waste Solvent Reclamation

Environmental Distillation Applications Through Modular Processing

Koch Modular specializes in the design and construction of complete modular process systems including solvent recovery applications. Our four decades of experience applying modular construction techniques and novel separation designs for a wide range of environmental waste applications ensures optimal solvent recycling systems for the specific needs of each client.

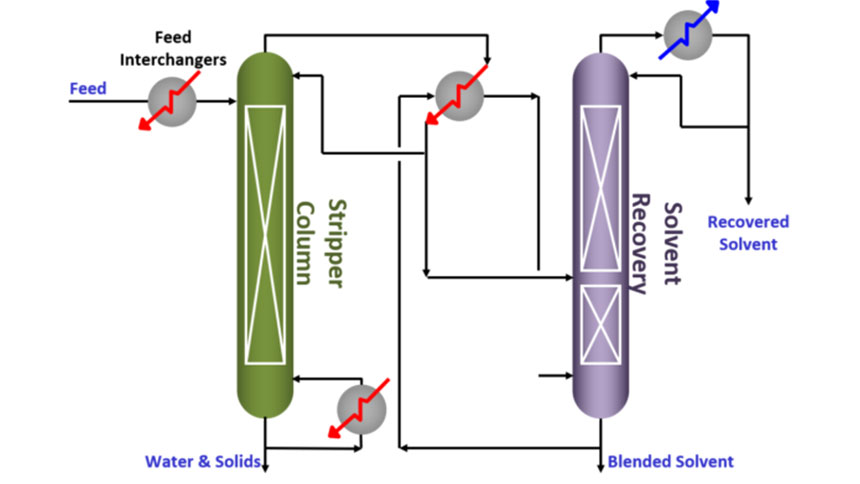

Typical Solvent Recovery System

This modular system is designed to operate in a semi-continuous mode to recover isopropyl alcohol (IPA), near it’s azeotropic concentration, from an aqueous process stream generated in the production of a pharmaceutical.

The system is subsequently operated in a continuous mode to dry the IPA, using azeotropic distillation with isopropyl ether as the entrainer.

What is Solvent Recovery?

Solvent recovery, also known as solvent recycling or solvent reclamation, is often a critical economic factor in determining the feasibility of a new project or plant expansion. Environmental regulations, new solvent costs and waste disposal costs can easily exceed the cost of solvent recovery equipment and operation. Koch Modular has years of experience a wide range of solvents. See below for a detailed list of our solvent recovery expertise. Our engineers excel at solving difficult new solvent recovery applications, including purification of solvents to virgin quality or better.

Koch Modular also provides process studies, laboratory and pilot testing, VLE development and complete process design engineering packages.

Solvent Recovery Services

Koch Modular’s unparalleled engineering approach has created solvent recovery systems for both hazardous and non-hazardous material separations to meet the industrial needs found in markets such as: chemical manufacturing, pharmaceuticals, biodiesel & biochemical, petrochemical, food, flavor and fragrance and beyond. Below you will find a detailed list of the various solvent recovery experiences we have for extracting raw materials from effluent.