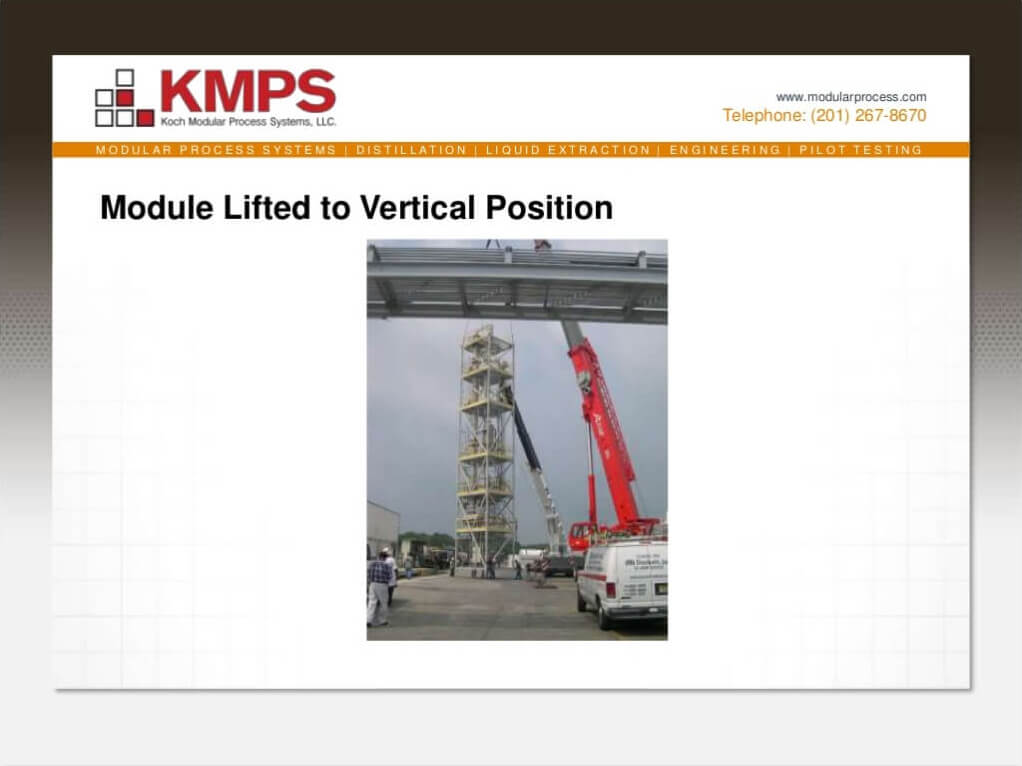

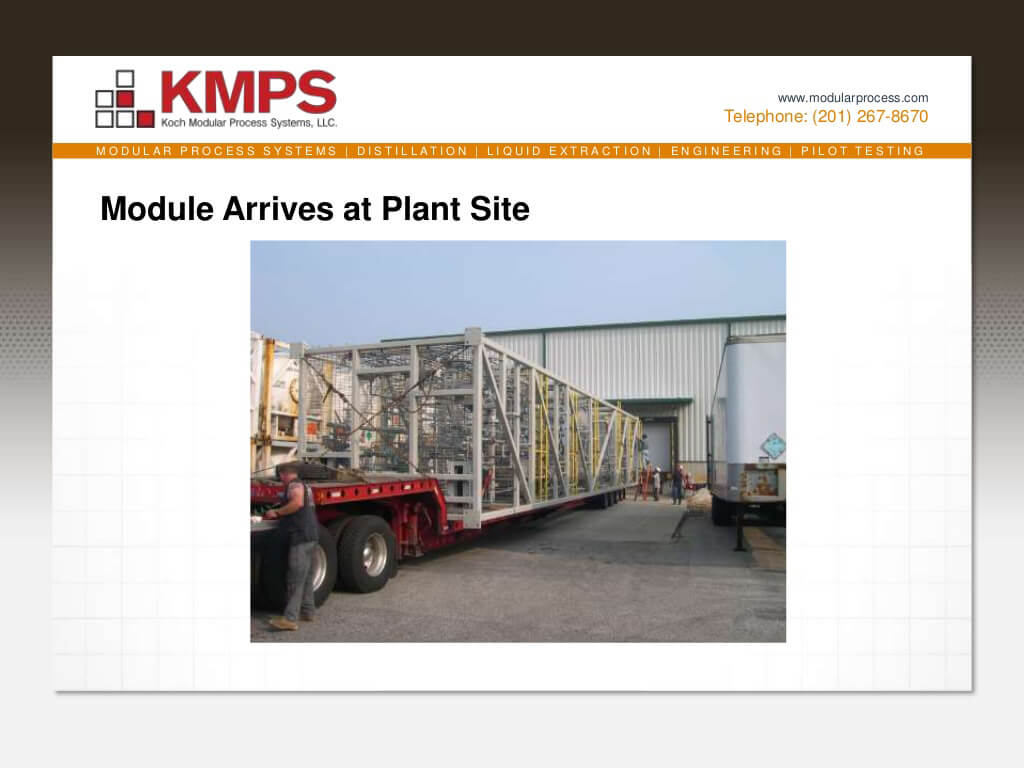

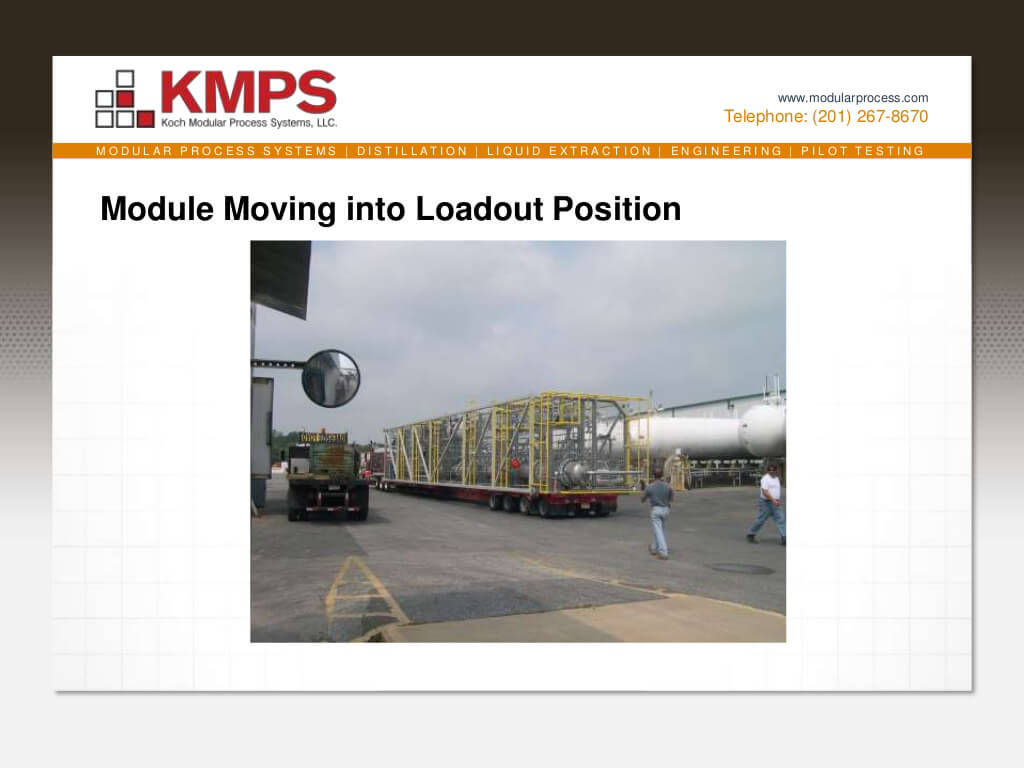

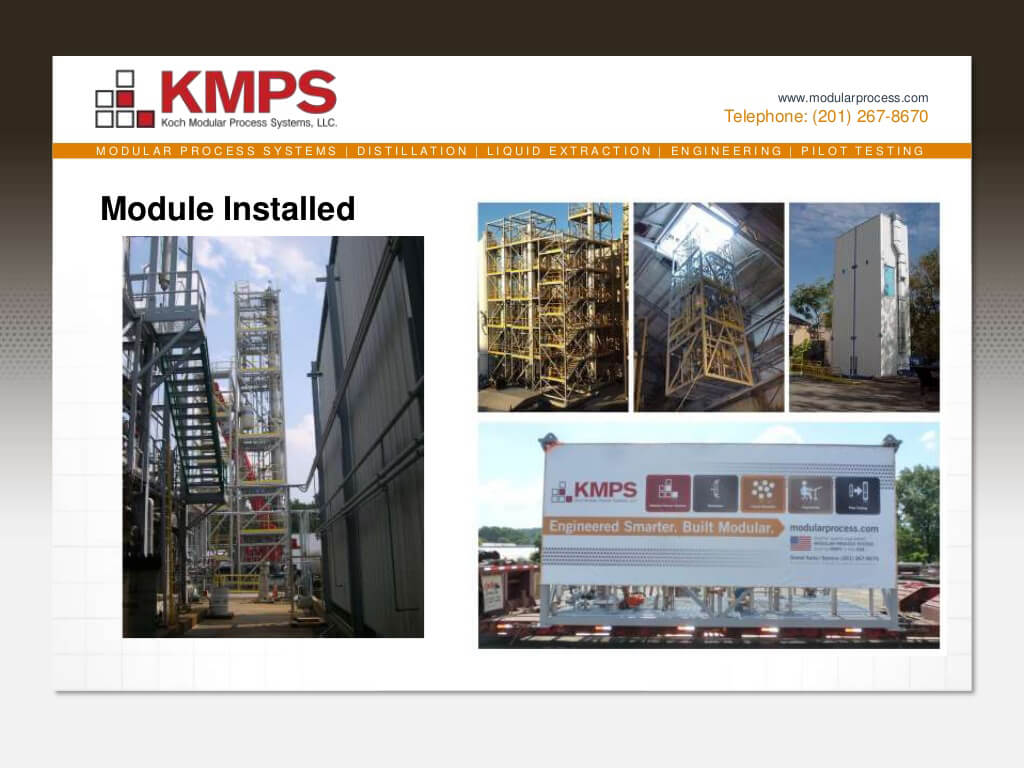

The typical modular system will include columns, reactors, drums, decanters, heat exchangers, pumps and other types of process equipment, all mounted within a structural steel frame. The structural steel frame serves as a shipping support and provides access to the equipment during normal operation and for maintenance purposes. After the process equipment is installed within the structural frame, the piping components, the field instrumentation, and the electrical wiring are completed.

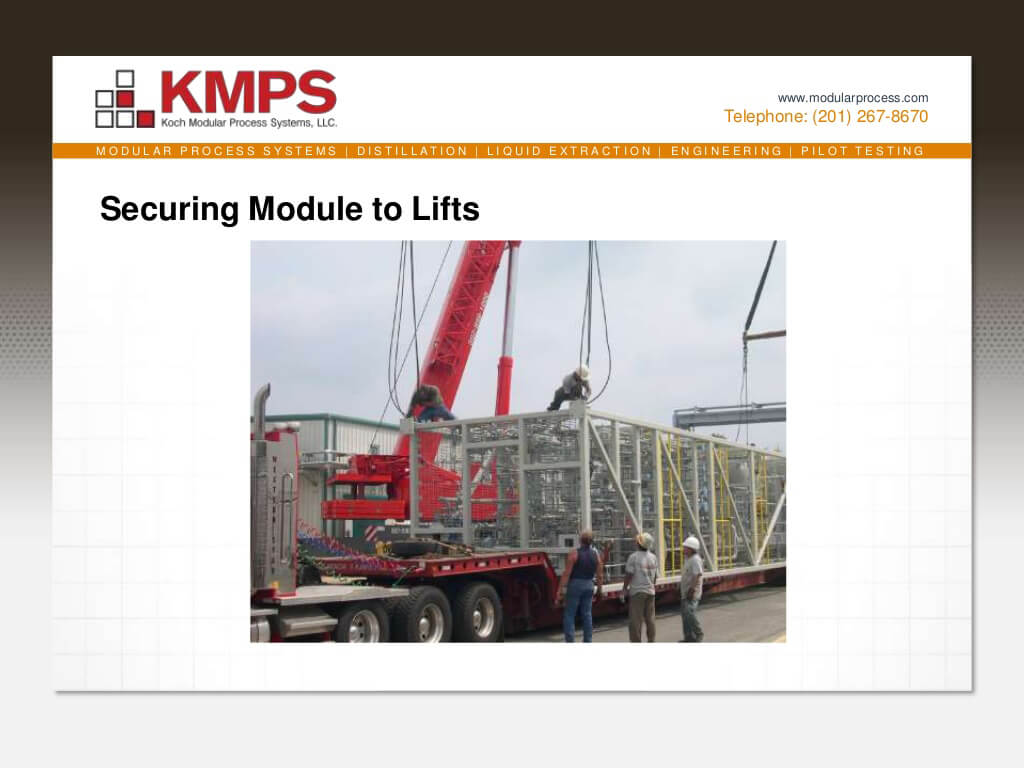

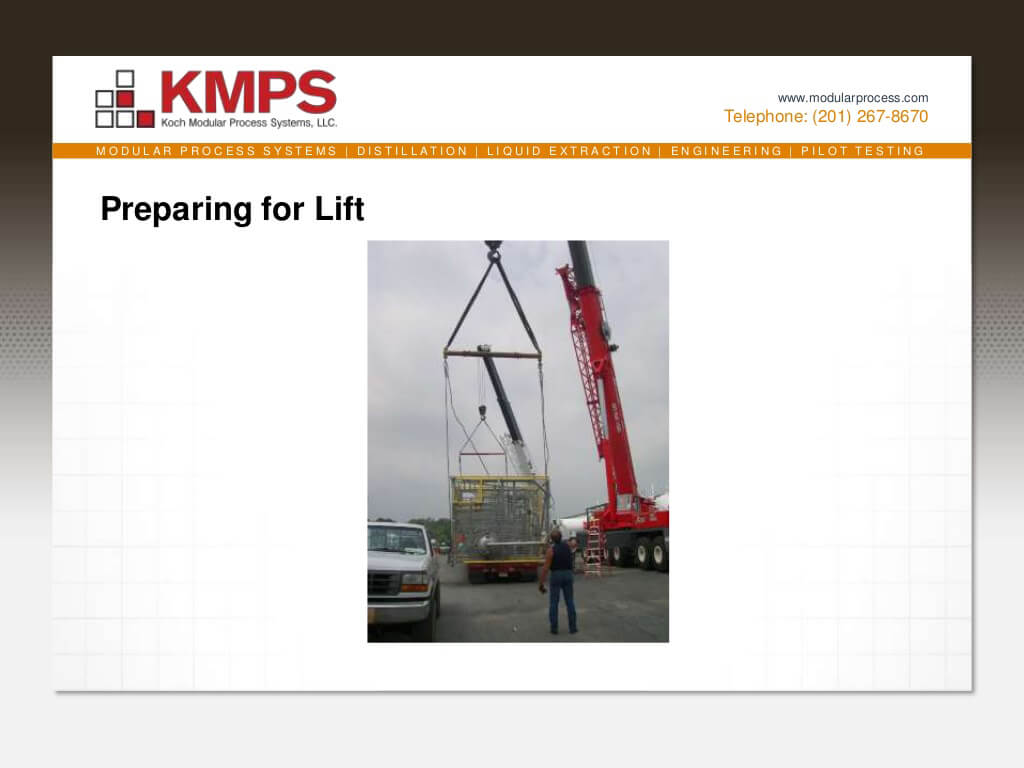

It is also typical for items like tracing, thermal insulation, lighting, control system, safety showers, and fire protection systems to be installed in the module at the assembly shop. A rigorous testing program is conducted on all these components before shipment to the field. The customer’s mechanical specifications, standards, and guidelines are followed in every respect, assuring each customer that the system provided will meet all of their expectations.