Efficiently Recovering Critical Materials & Rare Earth Elements

Engineering the Acceleration of the Energy Transition

As we shift towards a cleaner energy future, critical metals and rare earth elements are essential not only for energy security but also for supporting a wide range of industrial, technological, and defense applications. With the rapid growth of the clean energy sector, securing a reliable and sustainable supply of these materials is crucial.

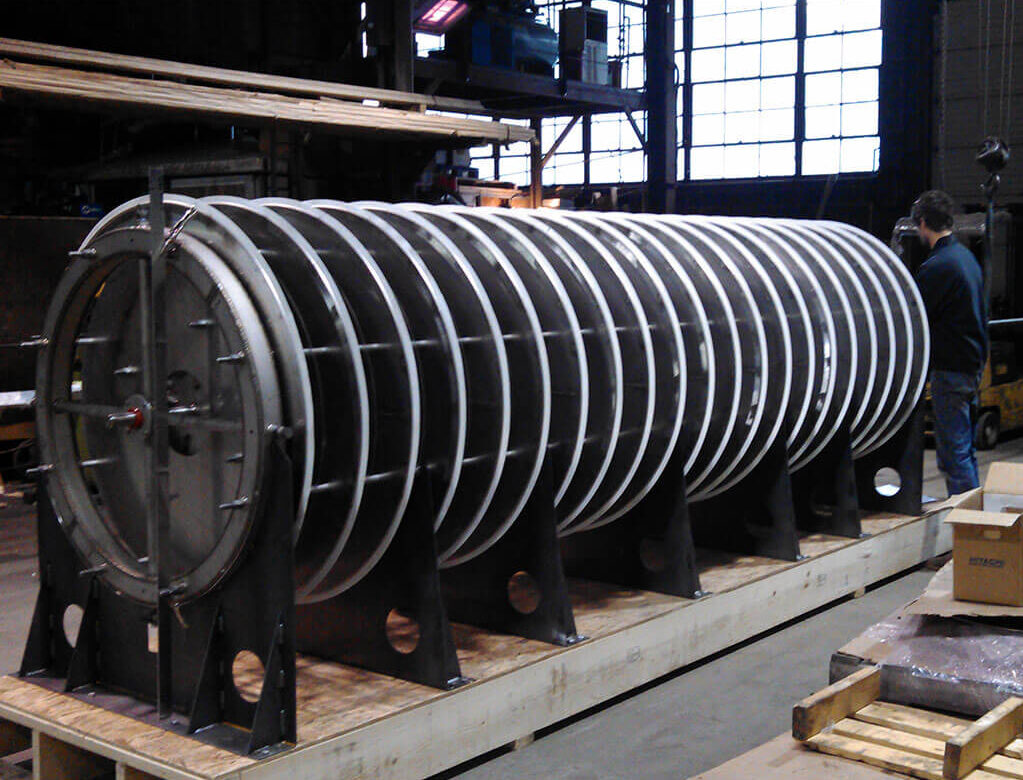

Koch Modular offers 60 years of engineering expertise. Our proprietary and proven technology facilitates the extraction of critical materials and rare earth elements from aqueous solutions derived from mining operations, electronic waste, and battery recycling processes, among others. SCHEIBEL® and KARR® extraction columns are highly efficient and cost-effective technologies that can replace traditional mixer-settlers to separate and recover critical materials and rare earth elements. Each extraction step in the hydrometallurgy solvent extraction process can be tested either at Koch Modular’s Pilot Plant in Houston, Texas, or at a client’s facility using pilot-scale SCHEIBEL® and/or KARR® columns.

Benefits of Transitioning from Mixer-Settlers to Agitated Extraction Columns

How it Works

A key aspect of any type of critical materials purification via SX is the selection of the appropriate solvent system. These solvents typically consist of an extractant for the specific material, a diluent to facilitate mass transfer, and, sometimes, a modifier to alter physical characteristics.

Once the optimal solvent is selected for the critical materials extraction process, equipment must be designed for the commercial installation. Multistage, continuous mixer-settlers have been the workhorse for many metal recovery processes used in mining operations, although agitated extraction columns are sometimes used in these processes. Agitated extraction columns offer significant advantages for critical materials and rare earth element processes which tend to be smaller in scale than large, industrial mining processes. These advantages include considerably smaller footprints and significantly reduced solvent inventories as well as improved efficiency.

With Koch Modular’s chemical separations and mass transfer expertise, particularly in the area of SX technology, and historical involvement in novel technological solutions in the field of advanced recycling, is well poised to contribute to the design of commercial solvent extraction equipment for the recovery critical materials and rare earth elements from aqueous solutions derived from mining operations, electronic waste, and battery recycling processes, among others. Koch Modular offers a number of different types of agitated extraction columns including KARR ® and SCHEIBEL® Columns. This allows Koch Modular to select the appropriate extraction technology for each individual application. In addition, the push to decentralize production, and thereby de-risk supply chains, is addressed via Koch Modular’s modularization expertise. Our modular design capabilities make it possible to locate processing plants near waste collection or generation sites.

Finally, we will engage in pilot testing to fully develop the process and provide a firm basis for design of the commercial extraction columns that is backed with a process performance guarantee.

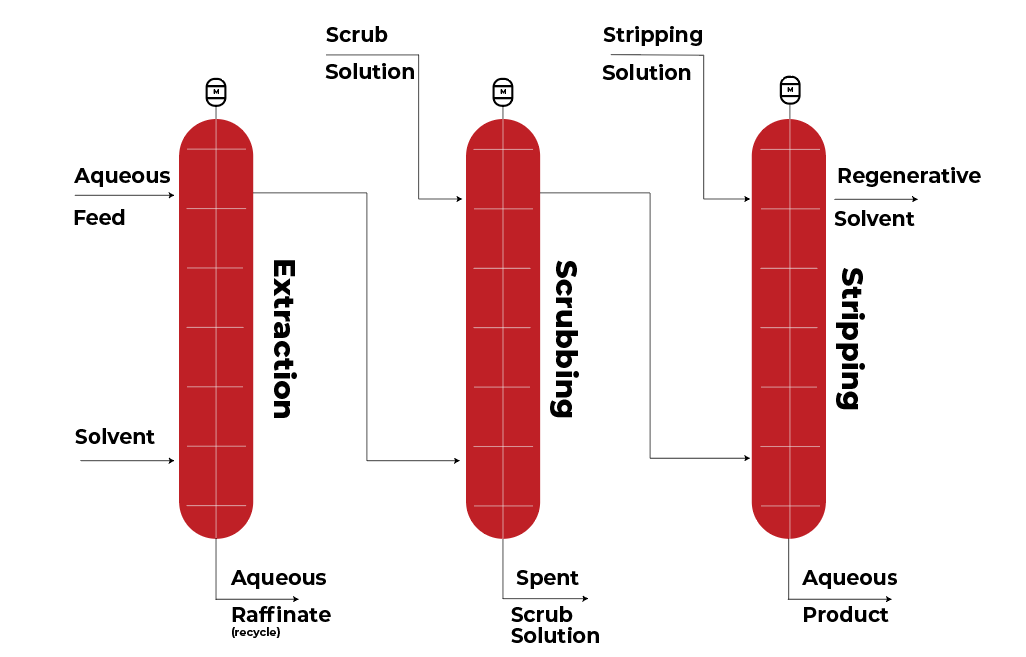

Typical Three-Column Recovery Process

Extraction

This step involves the selective extraction of the targeted critical material. At the end of the extraction process, the acidic raffinate is often recycled back to a digestive step.

Scrubbing

Removal of co-extracted contaminants, impurities, or other materials from the loaded organic leaving the extraction column using a pH-adjusted aqueous “scrub” solution.

Stripping

In this phase, the targeted material is extracted from the loaded organic using a pH-adjusted aqueous “strip” solution. The purified metal leaves with the spent strip solution, and the organic phase is often recycled back to the extraction step as regenerated solvent.