Custom Fabricated Heat Exchanger Examples

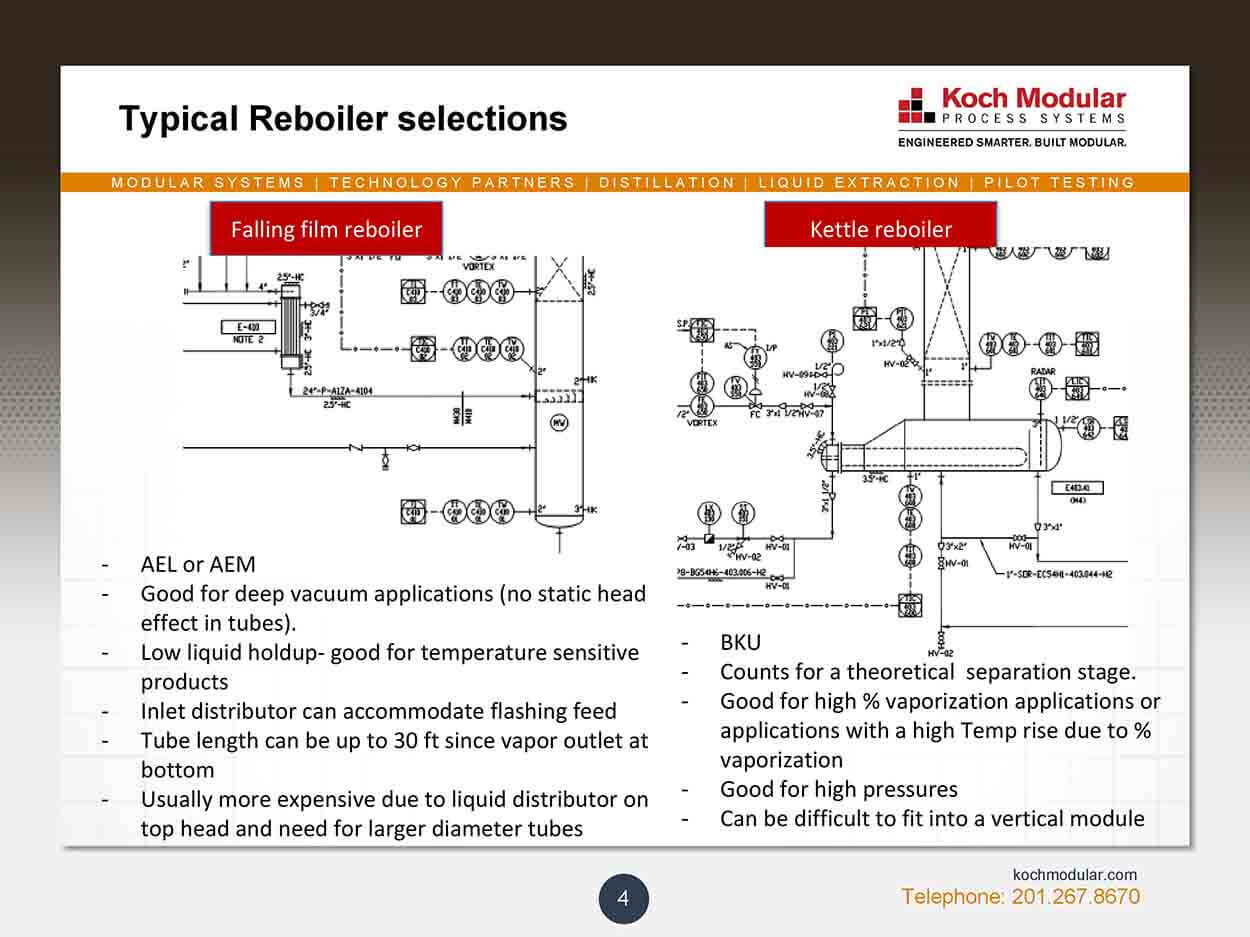

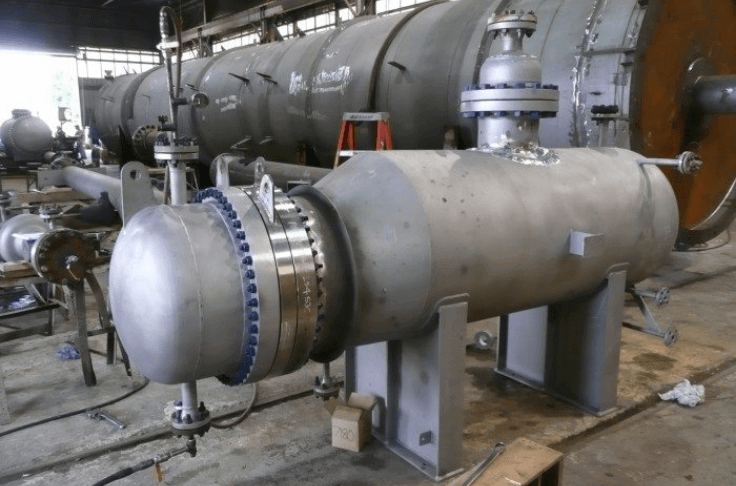

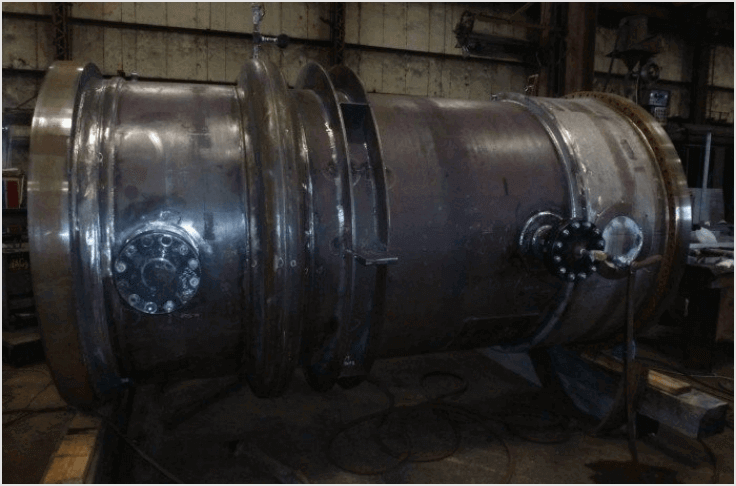

Kettle Reboiler

Common applications: evaporators, vaporizers, column reboiler

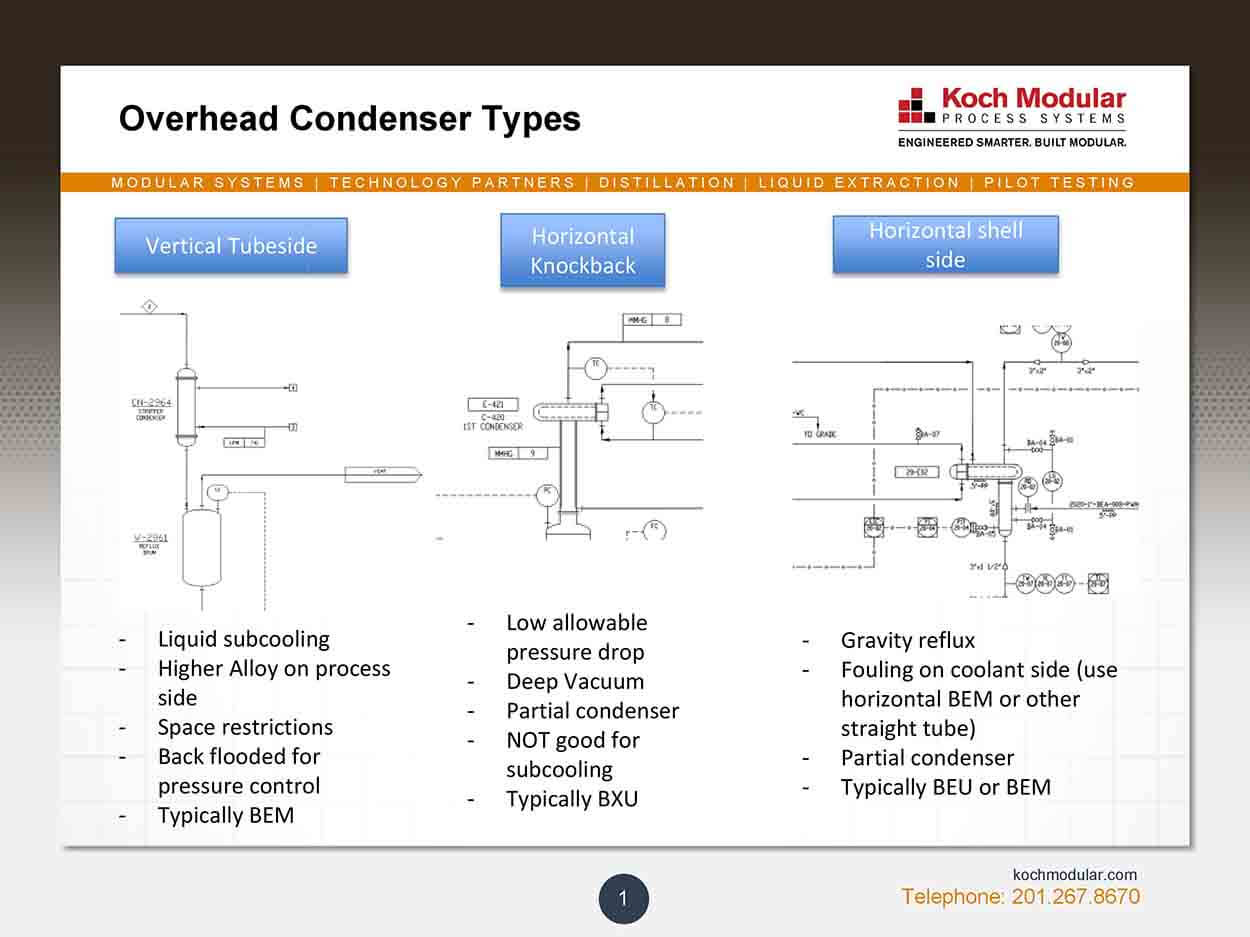

Shellside Knockback Condenser

Common applications: deep vacuum

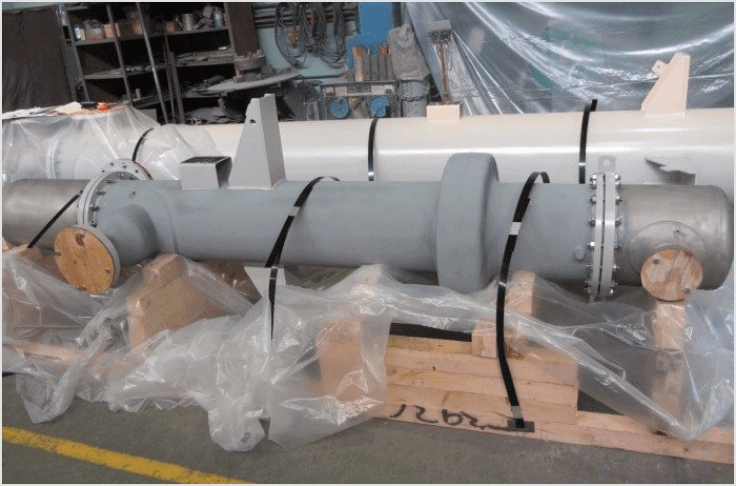

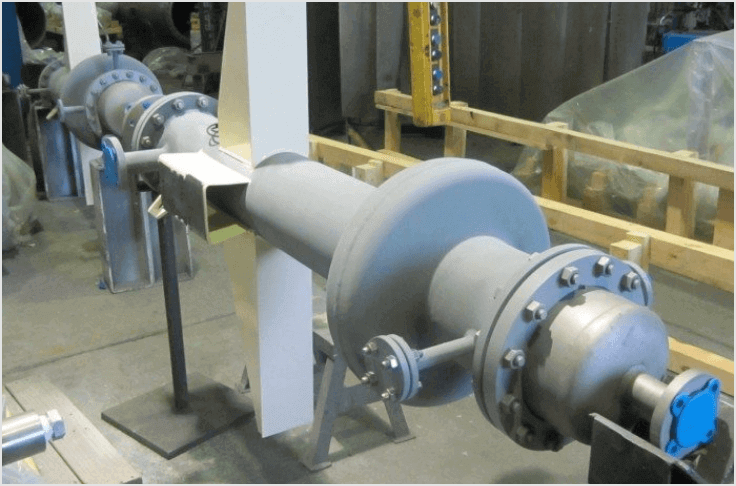

Straight Tube Forced Circulation Vaporizer

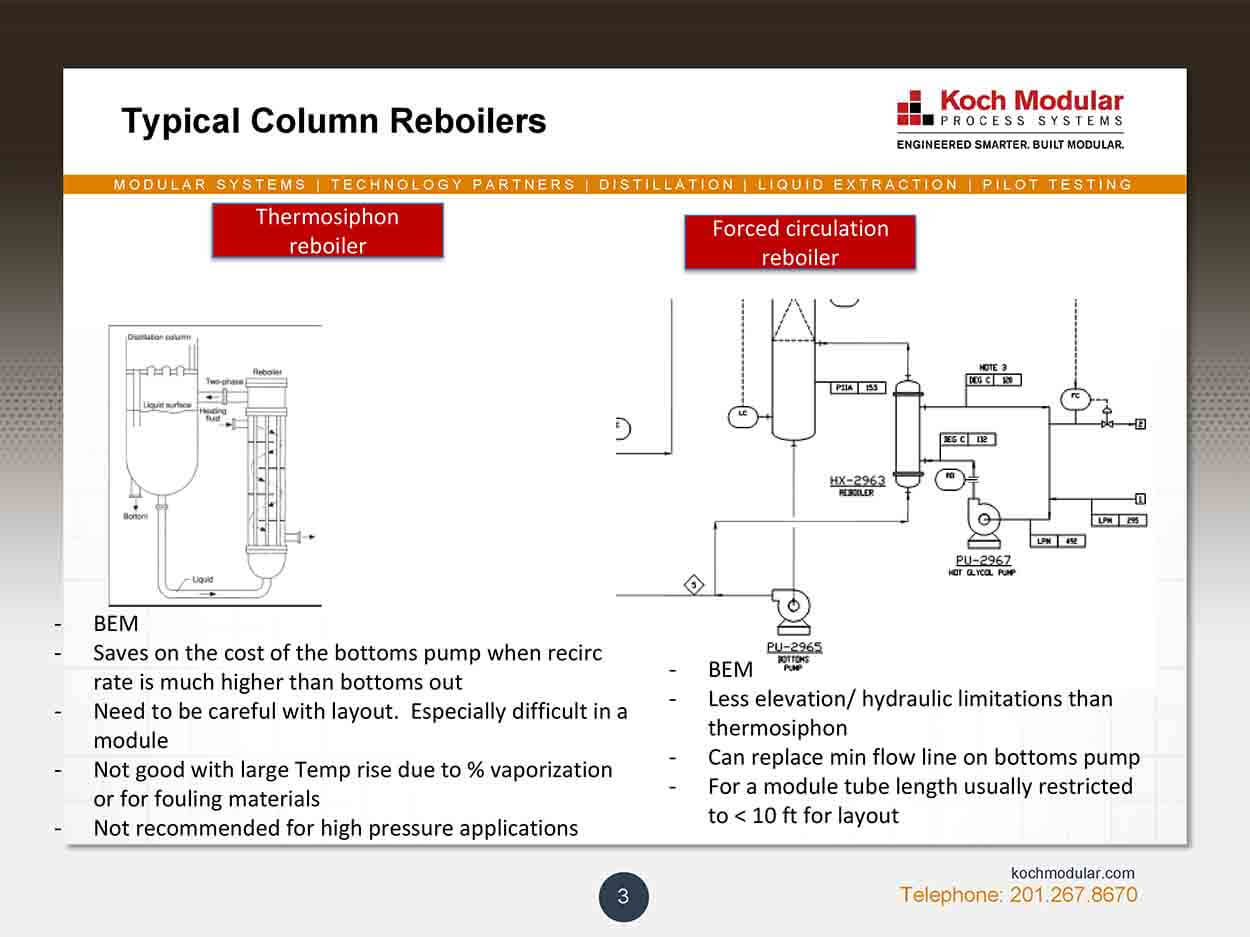

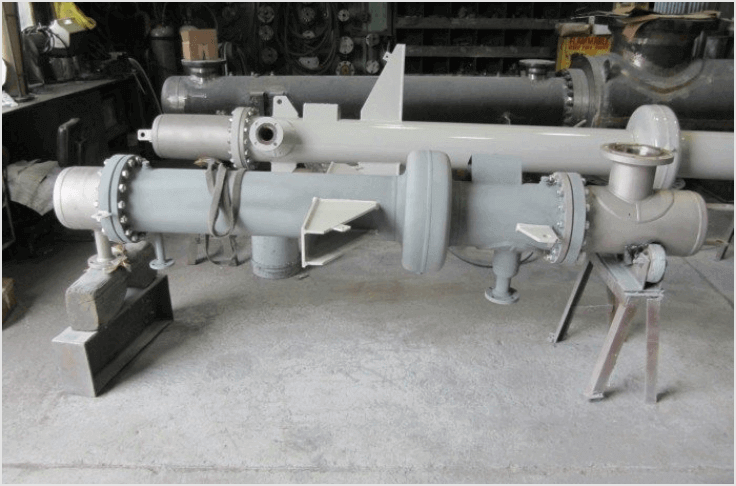

Straight Tube Thermosyphon Reboiler

Shellside Condenser with Double Tubesheet and Leak Detection Gap

Falling Film Reboiler with Distribution

Common applications: evaporators, column reboilers. deep vacuum, temperature sensitive materials

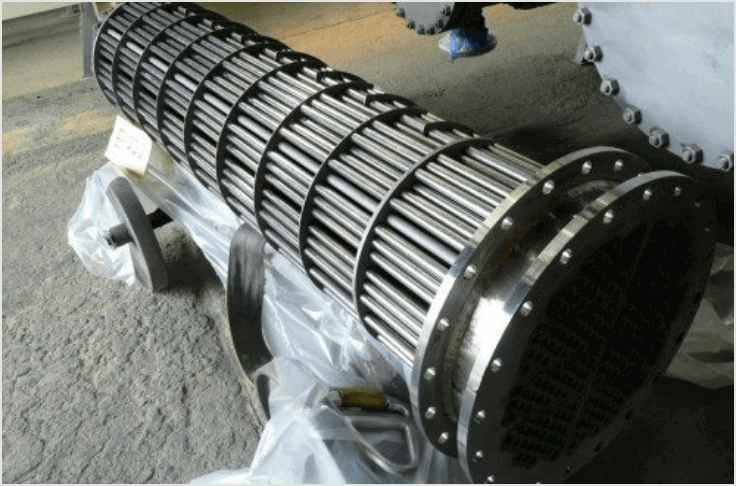

Double Tubesheet U-Tube Bundle

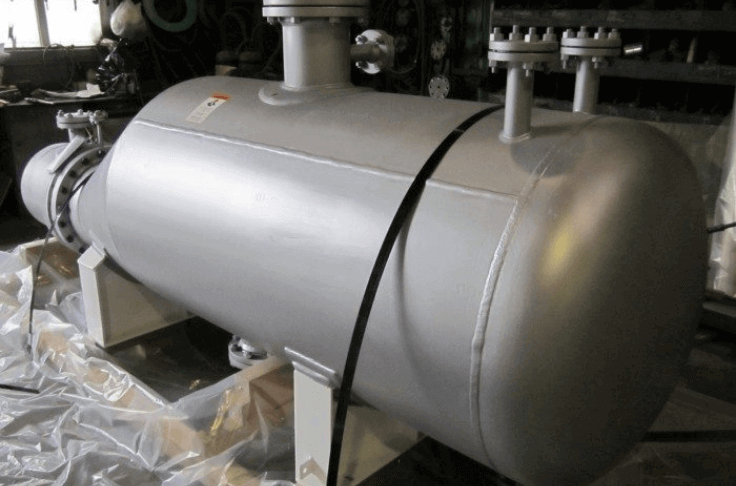

Kettle Reboiler with Double Tubesheet and Leak Detection Gap

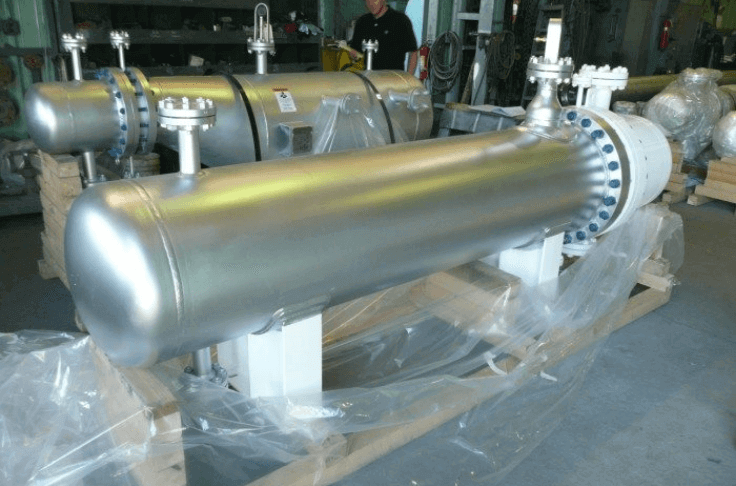

Straight Tube Interchanger

To get started with our optimized design please complete our online project inquiry form or fill up the detailed heat exchanger design form below. You can download the completed form using the download icon in the widget below.