PROBLEM

While Koch Modular engineers are capable of providing systems designed completely from scratch, they are also able to work with clients’ existing systems to lower project costs; this case is a prime example of that. The client had an existing column system and was looking to have it integrated into Koch Modular’s two-column extractive distillation system. This set the basis for the process design by informing all subsequent design considerations. This also led to integrating the instrumentation from the existing column into the modernized control system provided.

Furthermore, refrigerants transition from a low-pressure gas to a high-pressure liquid as they absorb heat during the refrigeration cycle. Consequently, at the time of the project, pilot testing with a glass pilot column was not possible, and the separation process was modeled with simulations instead.

PROCESS DESIGN

The overall process can be broken down into two primary steps: lights removal and extractive distillation.

During lights removal, the column provided by Koch Modular operates as a conventional distillation column with a midpoint feed stage, a rectifying section, and a stripping section. The feed to the column consists of 70.7 wt% R22 and 6.9 wt% R12, among various other refrigerants. The bottoms product leaving the column consists of 81.3 wt% R22 and 8.9 wt% R12, with much of the light compounds such as R115 and R125 removed, and subsequently serves as the feed for the extractive distillation step.

During extractive distillation, the column provided by Koch Modular now operates as an extractive distillation column. The R22/R12 azeotrope is broken with the use of an entrainer, which in this case is a higher boiling refrigerant. When the entrainer is mixed with R22/R12, it alters the relative volatilities by forming stronger intermolecular interactions with R12, allowing R22 to be driven overhead as a distillate product with 99.5 wt% purity. The bottoms product in this operating mode is a mixture of 96.3 wt% entrainer, 1.2 wt% R12, and any other remaining heavy compounds. Since the entrainer is not consumed in the process, it is adequately purified and returned to the extractive distillation process by using the client’s existing column.

It is important to note that the client’s existing column does not have the capacity as the new column provided by Koch Modular. As a result, in the extractive distillation mode, the new column is only able to operate at about half of the design capacity. In other operating modes such as lights removal, the new column can be operated at its full design capacity.

RESULTS

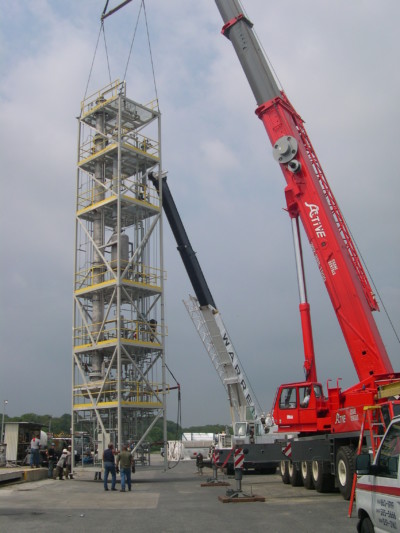

Koch Modular successfully provided a complete distillation system designed to continuously separate various refrigerant mixtures. The system was delivered on schedule and within budget. Startup was successful and the system has been running ever since with no reported issues

Leveraging the client’s existing column allowed for re-utilization of physical capital and resulted in reduced project costs. Although R22 has mostly been phased out, its recovery from a R22/R12 azeotropic mixture results in a resalable 99.5 wt% R22 product necessary for the millions of systems in the U.S. still using it as a refrigerant. In the case that R22 is completely phased out, the system provided can still be repurposed to separate other refrigerant mixtures of varying compositions.