PROBLEM

The system requested was a late addition to the client’s main, larger project that was already in progress; consequently, the design and manufacture of this system followed an aggressive schedule. A conventional construction approach was not preferred, as it would result in the delay of the main project by 6 to 8 months due to the lengthy air permit receipt process. As a result, Koch Modular suggested a modularized approach to allow fabrication to begin offsite prior to permit receipt and foundation completion.

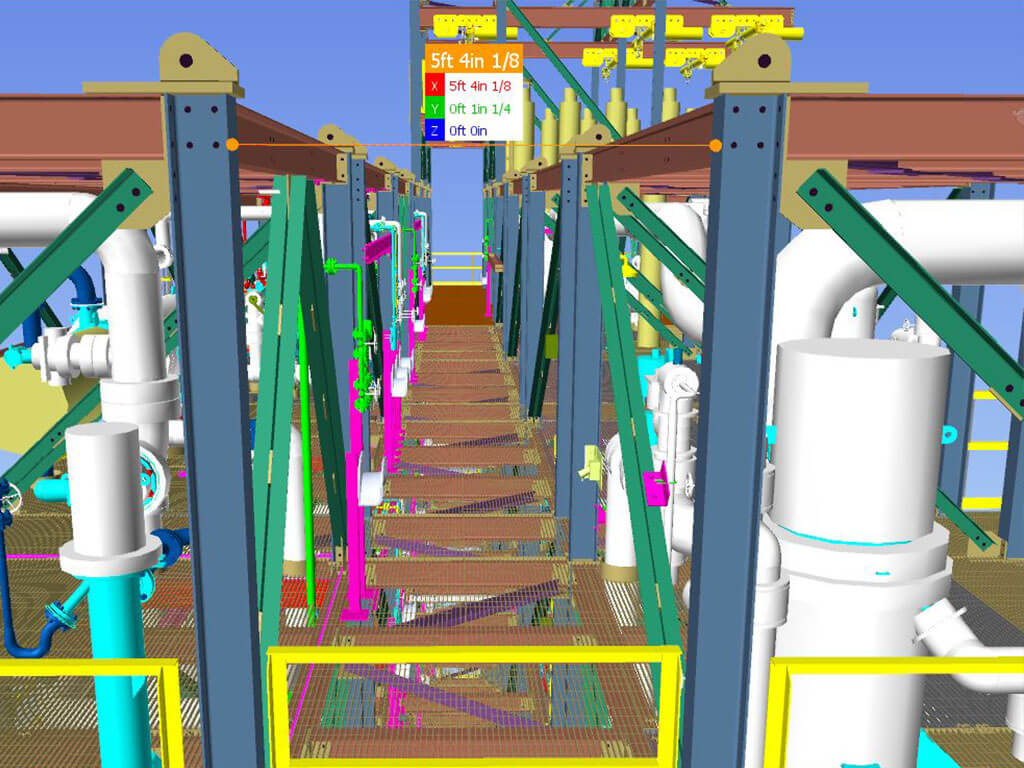

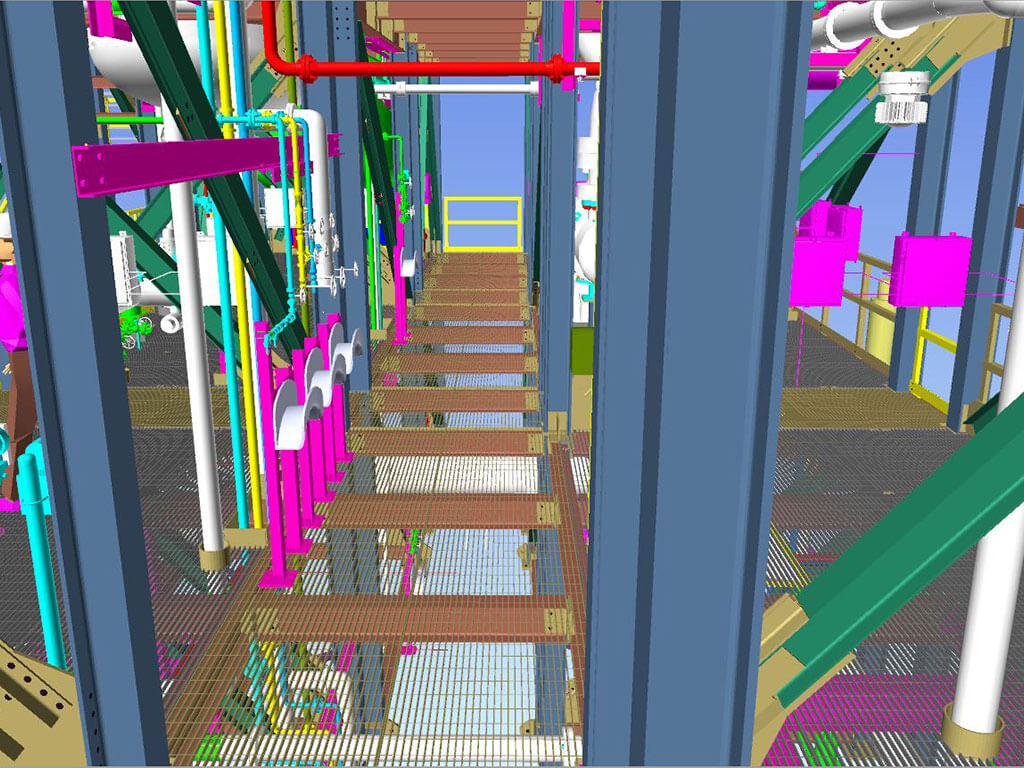

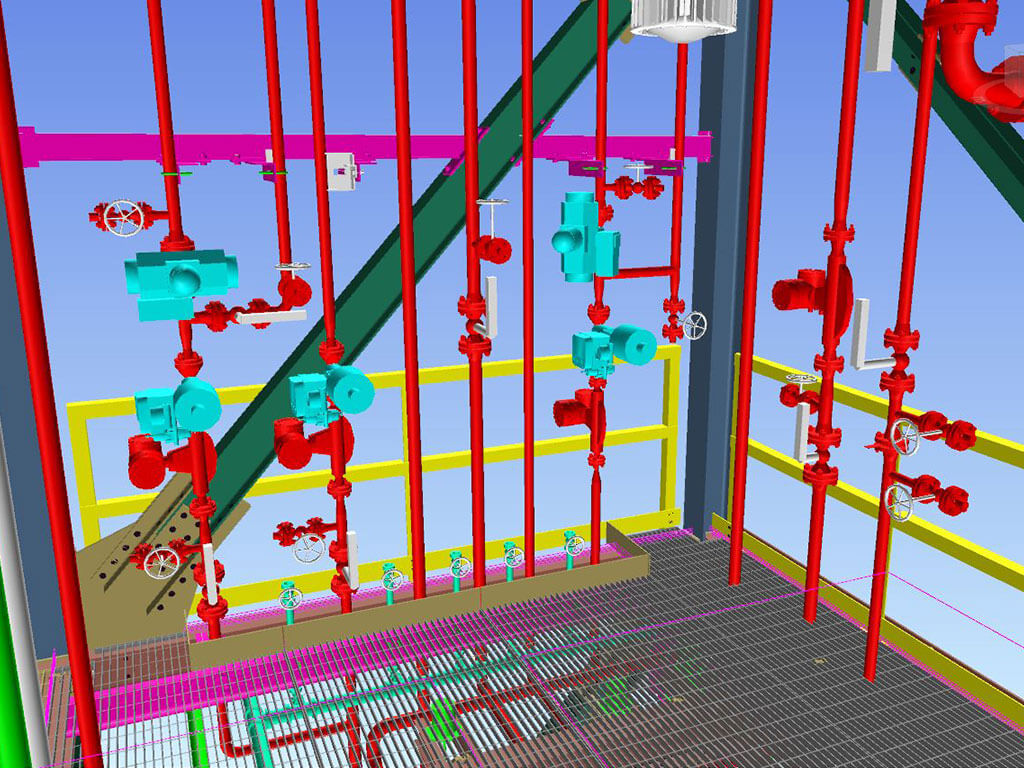

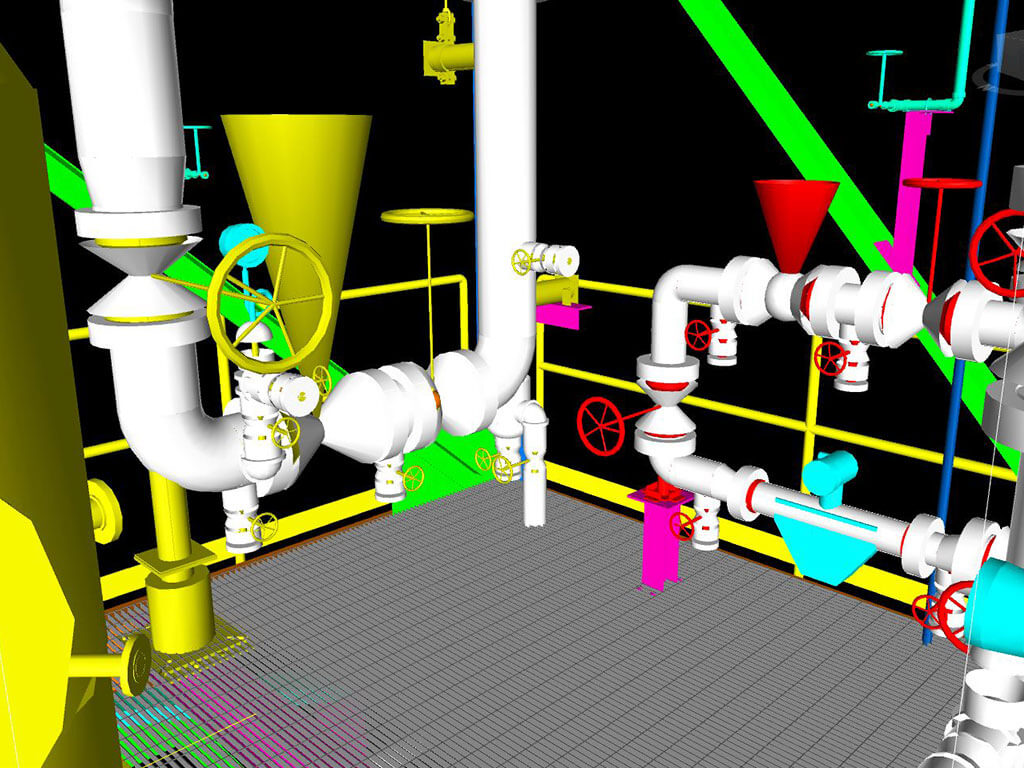

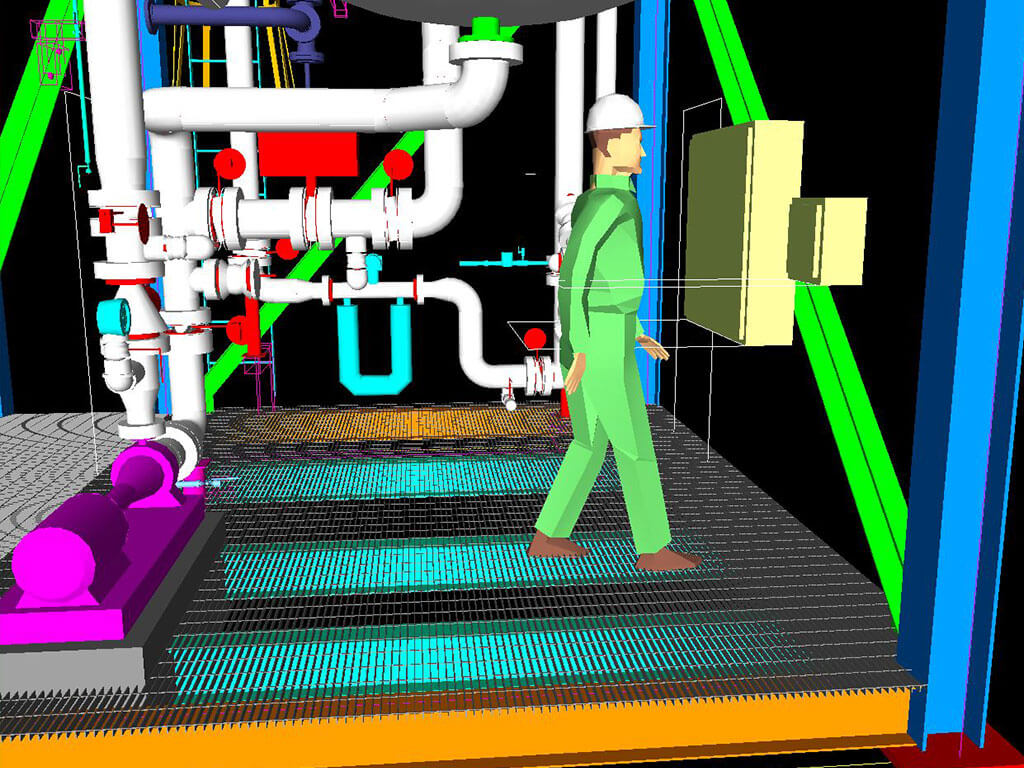

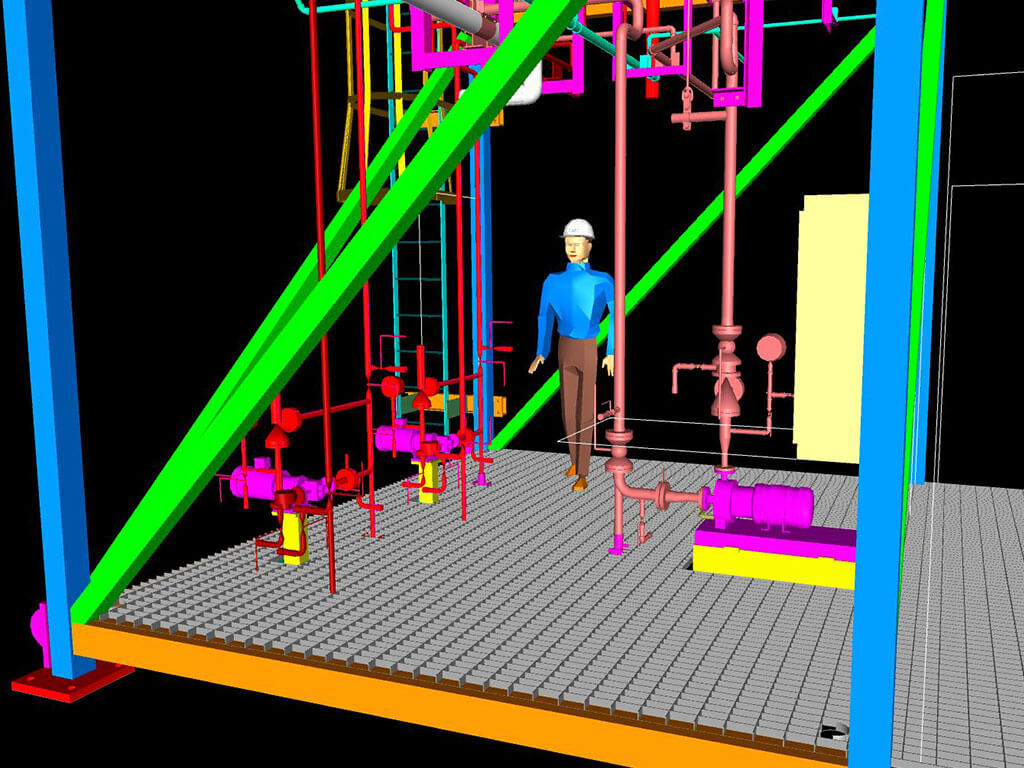

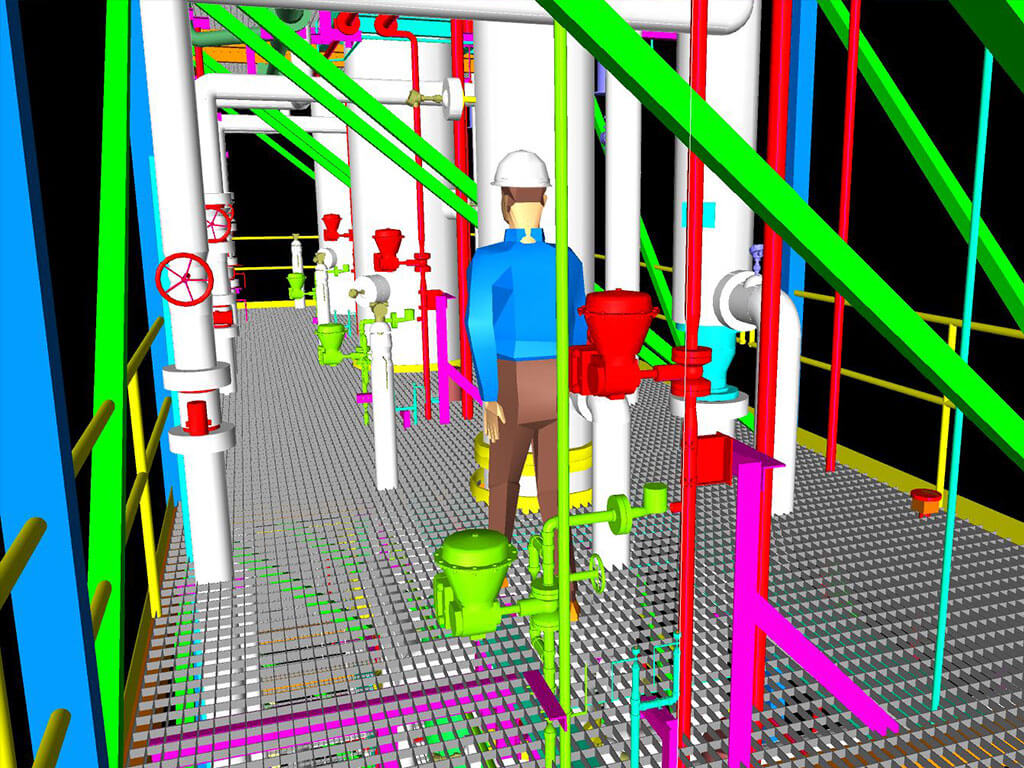

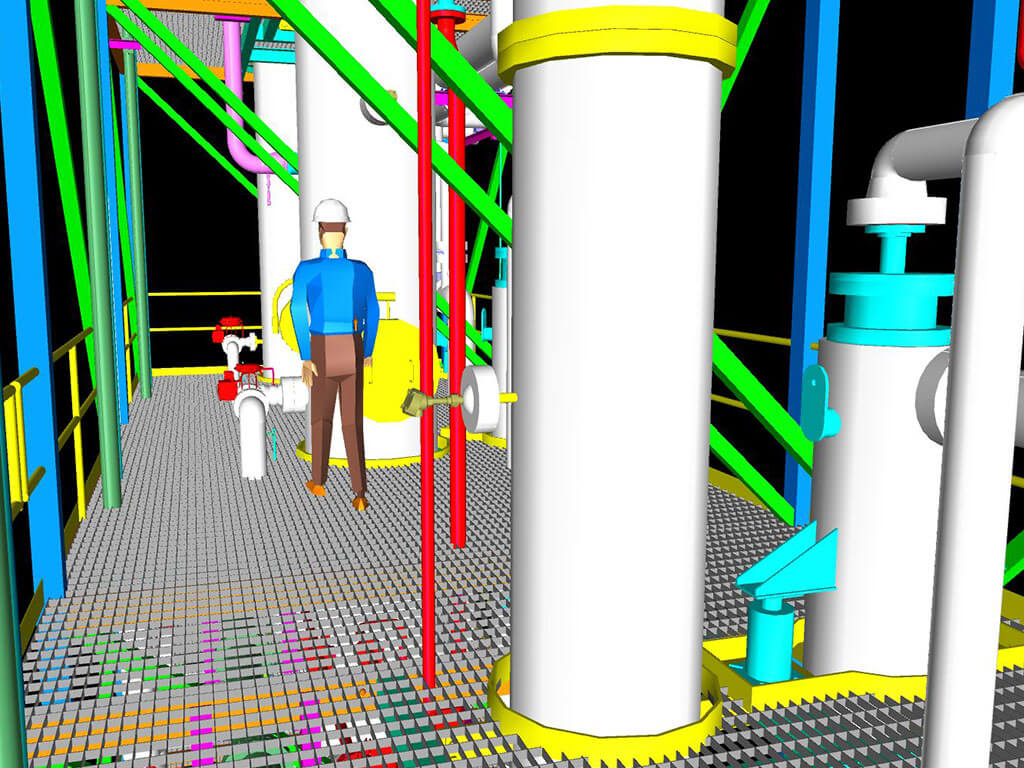

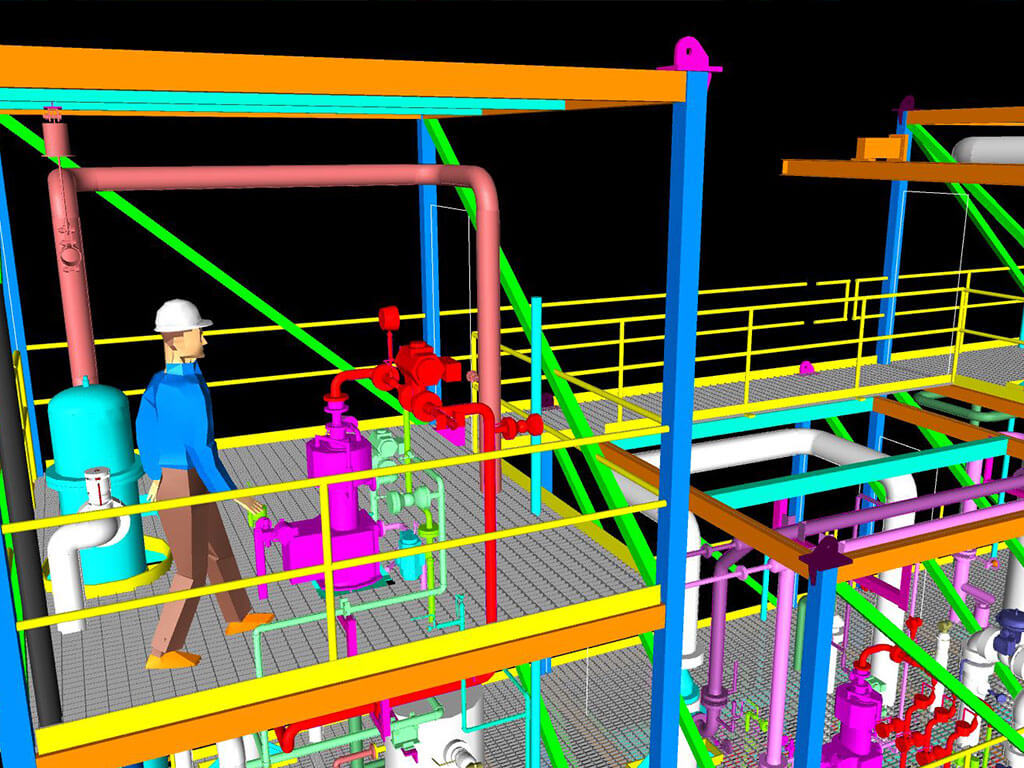

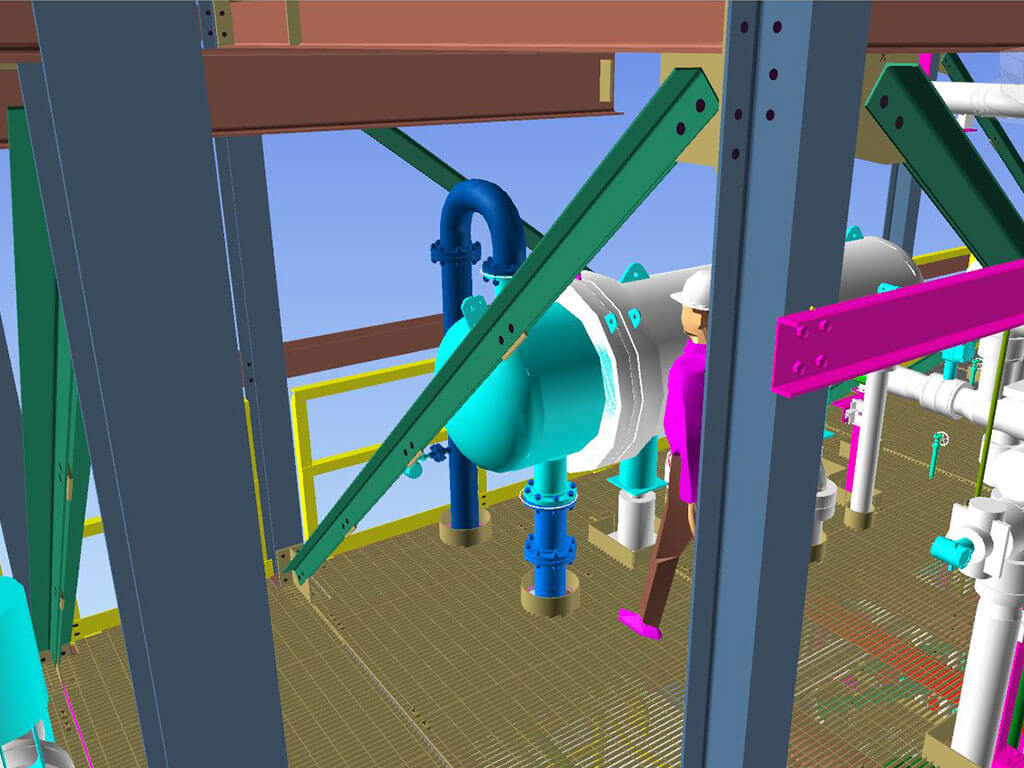

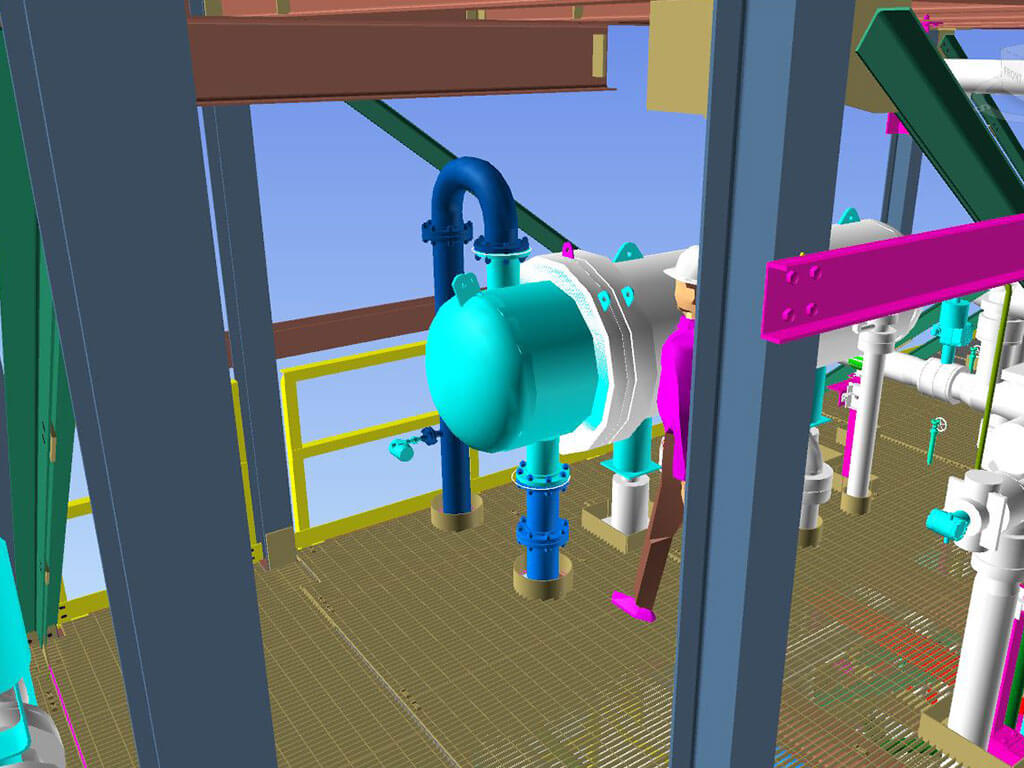

The client had never worked with a modular system supply firm that performed the process engineering as well as the detailed engineering design and construction. One of their main concerns was that the modular system would not have sufficient space for operability and maintainability, with adequate access to process equipment, piping and instruments. Furthermore, they were concerned that interior cross bracing on each individual module would interfere with access and movement within the complete structure and requested that multiple access and egress pathways be available between all modules at all floor levels. They also requested that the ground floor be concrete and free of any steel supports, i.e. appear as though it was a field erected base with pumps on concrete pads.

SOLUTION

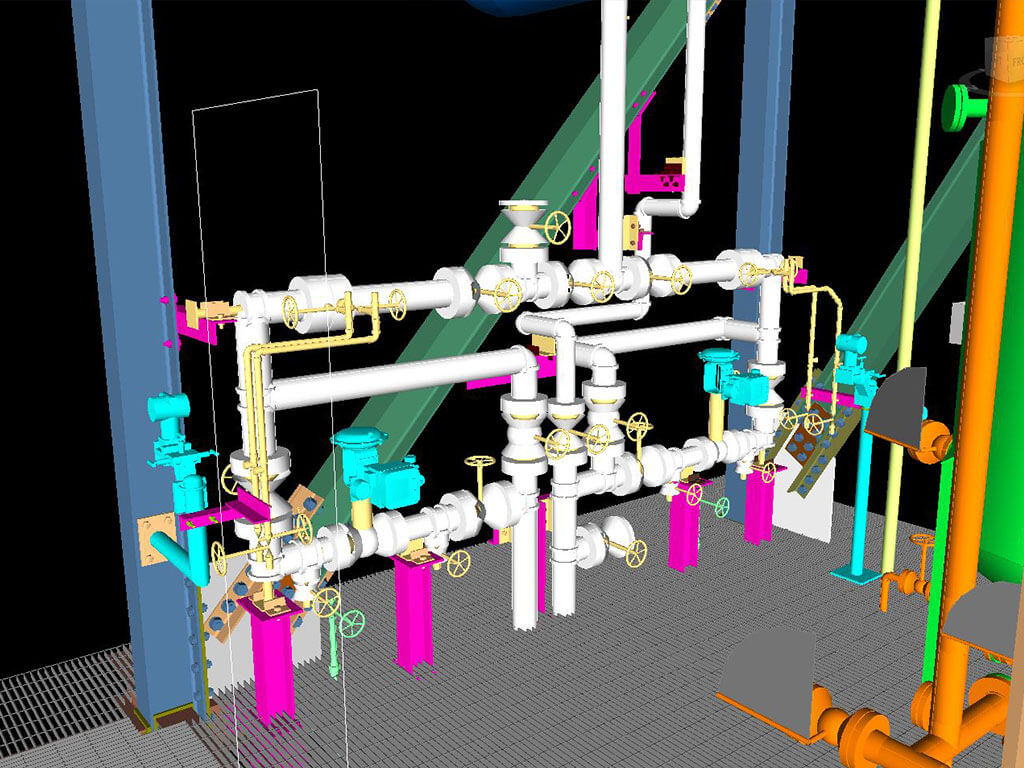

The process design of the system was optimized, generating a product with greater than 99.5 wt% purity. The system also recovers the solvent used from a recycle column at greater than 85 wt% purity. The process consists of an exothermic reaction taking place in a pumped reactor loop, followed by various purification steps for the recoveries of purified chlorinated hydrocarbon product and unreacted solvent.

RESULTS

The modular system provided by Koch Modular was ultimately based on a collaborative optimization with the client and it provided a purified product while addressing all of the client’s initial concerns about access to equipment.

Spatial concerns were resolved with careful design that minimized cross bracing on interior module faces and maximized space for access to process equipment, piping, and instruments. Additionally, two means of egress for each module and walkways between modules were provided. The aggressive project schedule was maintained, and the system was delivered well in advance of the completion of the main facility. There were also some cost savings realized versus conventional construction.

The system installation was a success and it has been running ever since with no reported issues.