This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Challenge

Each project presents a unique set of challenges that Koch Modular engineers are well-equipped to take on. For example, the separation of an IPA/water azeotropic mixture is difficult and cannot be achieved by conventional distillation methods. Also, this IPA recovery system requires operating flexibility, first operating as a batch process to approach the desired azeotropic composition, followed by a continuous process to introduce the appropriate entrainer into the mixture. There were additional specifications, such that the system is multipurpose, can perform different separations, and has automated start-up and shutdown. Acknowledging that the client harvests pharmaceutical components from pig intestines, Koch Modular engineers also paid special attention to proper solids handling to avoid any fouling and accounted for inconsistencies inherently present in natural materials.

SOLUTION

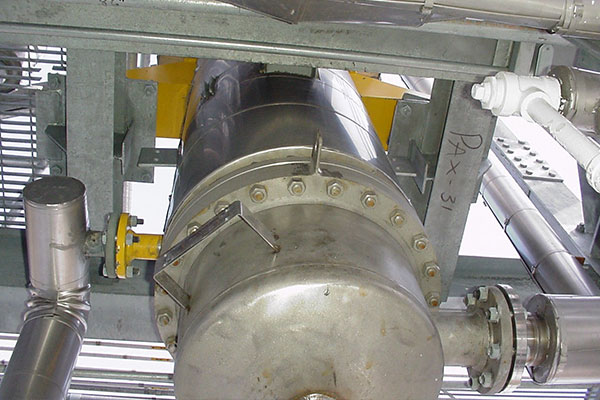

Koch Modular provided two modules as part of a system designed to perform an azeotropic distillation on an IPA/water azeotropic mixture. The system first operates in a batch mode to recover IPA, near it’s azeotropic concentration.

The system is then operated in a continuous mode to dry the IPA using azeotropic distillation with IPE as the entrainer, producing a product stream of 96 wt% IPA, 4 wt% water and trace DIPE. An IPE/water heterogeneous azeotrope is also formed and subsequently separated by decanting.

RESULTS

The recovery and reuse of IPA provide an opportunity to reduce waste solvent disposal costs and meet increasing environmental and commercial pressures imposed on the pharmaceutical industry.

The system provided successfully operates in both batch and continuous processes, achieving the difficult separation of an azeotrope, appropriately handling pig pancreas solids, and mitigating any fouling during the solvent recovery.