PROBLEM

Designing a system that can process citrus oils under various modes of operation can be challenging, and doing so under deep vacuum can be even more so. While vacuum distillation allows for the purification of products not readily distilled at ambient pressures, the equipment needed tends to be more complicated and a more sophisticated control system is needed to maintain a low pressure differential. System complexity can result in further challenges in maintenance, such as in cleaning between feeds, and, combined with the client’s overall module height specification, requires deliberate thought put into equipment and piping design. Additionally, it is important to note that the procurement of project resources was completed during the COVID-19 global pandemic when there were many opportunities for supply chain issues. Adhering to the project schedule and budget required strategic foresight and extensive planning with the client and suppliers.

SOLUTION and RESULTS

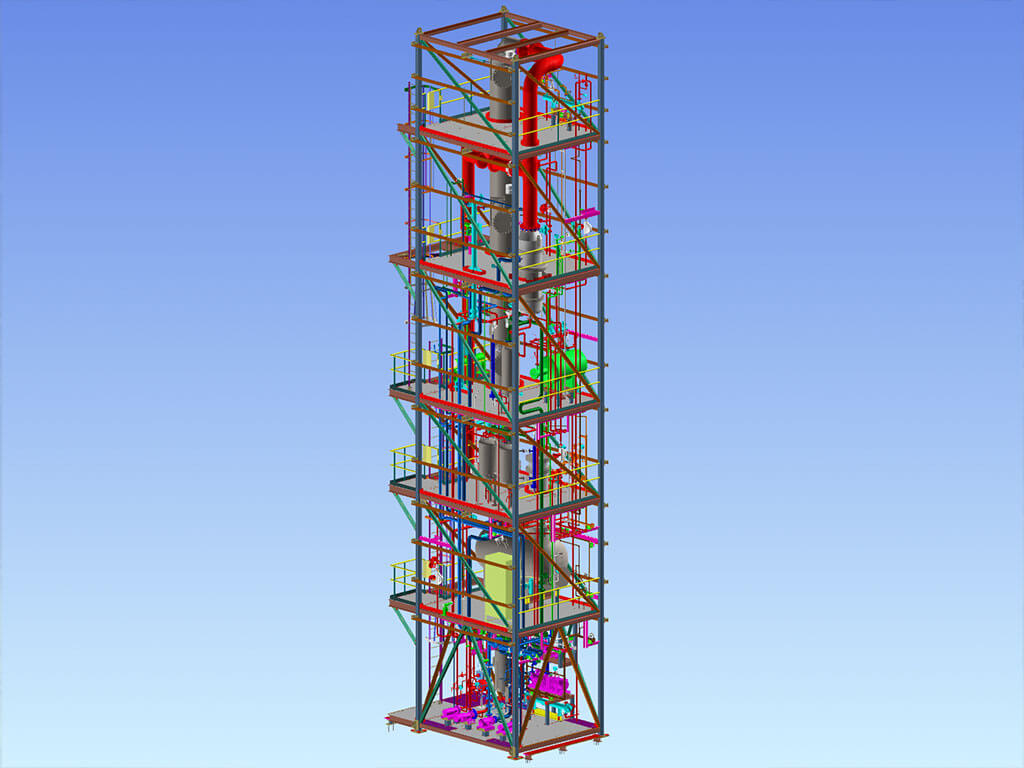

Koch Modular designed a multi-purpose citrus oil vacuum distillation system that can operate at a range of pressures and loadings, and can produce various high value citrus oil cuts. The system was designed to be fully automated, allow ease of access for maintenance, and have fully drainable lines and equipment in addition to two feedpoint options and a side-draw takeoff outlet. As a result, of the automation used the operator does not have to climb to change the configuration of the feed and product locations.

Cleaning between different feeds is easily performed. Giving special attention to piping design and using pumps with small base plates was also critical in condensing the system size to fit into a 12 feet x 14 feet foot print and a height of 72 feet. A combination of siding and mesh around the module was provided for privacy.

Vacuum distillation is particularly useful when working with temperature-sensitive products, such as citrus oil. Low pressure drop was optimized with maximum capacity, minimizing both batch time and product temperature. Overall, a faster processing time, processing without thermal degradation, and a reduction in energy consumption was achieved with this system.

Issues and possible delays regarding supply chain were avoided due to strategic planning and constant communication with suppliers. Koch Modular project and process engineers received authorization from the client to order supplies earlier in the timeline.

The system was installed on time and is meeting performance.