This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Challenge

Although designing distillation process is standard for Koch Modular engineers, this project presented some unique nuances. A distillation column and its associated falling film reboiler were both designed with low pressure drop to mitigate any appreciable temperature increase. This was also necessary to avoid degradation of a complex biodiesel feed that consisted primarily of fatty acid methyl esters. Furthermore, the process required heat integration to limit the amount of heat put into the process and make the process more economically favourable from an OpEx perspective.

SOLUTION

Koch Modular process engineers tackled the design requirements by creating a pump-around loop system that would limit the pressure drop in the upper section of the column and act as a direct contact condenser and allow for additional heat integration. The pump-around loop consisted of pumping the liquid side draw from the middle of the column through multiple heat exchangers and pumping it back to the top of the column as a subcooled liquid. A falling film design shell and tube reboiler with hot oil as the heating utility in the shell and column bottoms flowing through the tubes was used to partially vaporize process material with minimal pressure drop. This allowed for a minimal increase in temperature of the process material flowing through the reboiler.

Additionally, using multiple heat exchangers allowed for a thermally efficient system that conserves the amount of heat put into the process. The distillation column itself was designed with several different types of structured packing and several robust liquid and vapor distributors to minimize pressure drop across the column and maximize its separation efficiency.

RESULTS

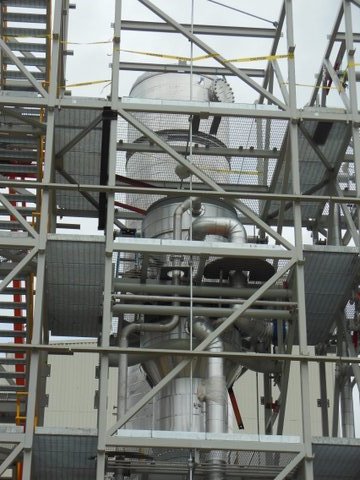

In the end, Koch Modular supplied a modular biodiesel distillation system consisting of a free-standing distillation column within a 36-week schedule. The system was designed to process biodiesel feed which reduced monoglycerides to 0.1 weight % or less in the distilled biodiesel product stream.

The system achieves this through vacuum distillation while also removing the majority of the methanol, diglycerides, triglycerides, non-volatile residues and a limited amount of the free fatty acids -further purifying the biodiesel product stream. The system was delivered on time and ran successfully for several years after getting through the process startup phase.