PROCESS

Koch Modular Process Systems has extensive experience in designing carbon capture systems. The basics of this type of process is as follows:

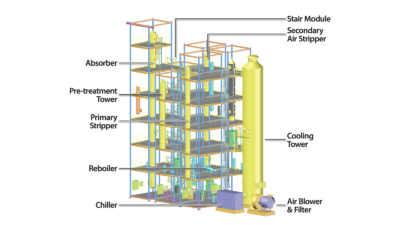

Raw flue gas enters an absorber where a regenerable solvent removes CO2 from the gas. The clean flue gas then leaves the absorber and is vented to the atmosphere. The rich solvent is sent to a reboiled regenerator where the vapors produced strip the CO2 from it, leaving a regenerated lean solvent stream. The regenerated solvent is returned to the absorber to complete the circuit. CO2 liberated in the stripper is then sequestered.

PROBLEM AND SOLUTION

One of the main challenges of this project was designing the system such that it can accommodate different solvents to run varying carbon capture studies. The built-in flexibility was crucial for the client to effectively gather extensive data for technology scale-up. Koch Modular accommodated for these constraints in the design process, and provided a pilot plant with columns that are 28”-30” in diameter. The unit provided is designed to treat 2400 scmh of raw flue gas using a heat integration method coupled with various amine solvents. The CO2 capture process utilizes two-stage stripping for solvent regeneration as well as a heat integrated cooling tower system.

RESULTS

Ultimately, Koch Modular delivered this fixed-price project on time and within budget. The pilot plant provided successfully proved and demonstrated the client’s carbon capture process, and allowed the client to take major steps towards the commercialization of their new technology.