Engineering Experience in Distillation, Extraction & Steam Stripping

Koch Modular’s engineers excel at tackling and solving the toughest separation problems. We consider non-ideal mixtures as “run of the mill” challenges due to our years of experience in finding the best possible process solutions.

Below is a partial list of compounds that Koch Modular Engineers have experience with:

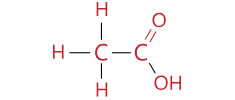

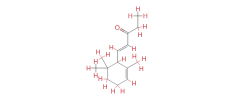

Acetate Esters

Acetate esters have the general formula CH3CO2R, where R is an organyl group. Derived from an organic acid in which one (-OH) hydroxl group is replaced by the (-O-alkyl) alkoxy group. Typical solvent recovery application.

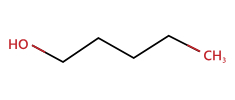

Alcohols

Organic compounds containing the hydroxyl group (–OH) bound to carbon. Typical solvent recovery application.

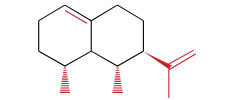

Aliphatics

Organic compounds, also known as “non-aromatic”, are open-chain saturated or unsaturated containing no rings typical of the aromatic compounds. Typical steam stripping application.

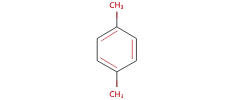

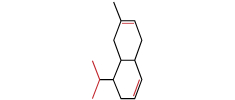

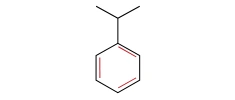

Aromatics

Unsaturated organic compounds characterized by one or more planar rings of atoms joined by covalent bonds of two different kinds. Typical steam stripping application.

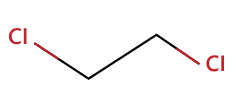

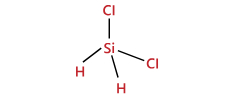

Chlorinated hydrocarbons

Group of chemicals composed of carbon, chlorine and hydrogen. Typical solvent recovery application.

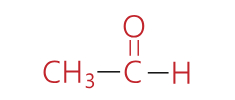

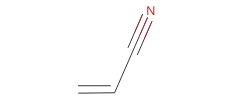

Ketones

Organic compounds containing a carbonyl group (a carbon-oxygen double bond). Typical solvent recovery application.

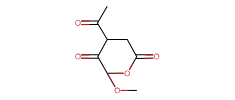

Phenolics

Aromatic organic compound consisting of a hydroxyl group (-OH). Typical solvent recovery application.

Biodiesel

Applications including product purification, methanol recovery and wastewater stripping.

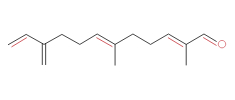

Citrus Oils

Folding and specialty fractionation of a wide variety of citrus peal oils and other fragrance compounds requiring deep vacuum applications.

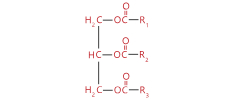

Fish Oils

Oleochemical production and purification, including omega 3 fatty acids (DHA, EPA). Most of these applications are dependent on deep vacuum distillation because of the thermally sensitive nature of these compounds. Through extensive research and practical application, Koch Modular’s technologies have been developed to execute such advanced distillation techniques as required.

Acid Gases

Koch Modular has extensive process engineering and modular system design experience in acid gas, sour gas and carbon dioxide (CO2) removal/recovery applications. This includes the first ever operating carbon capture and storage facility.

Electronic Specialty Gases

Complete modular process plant systems to meet the purification, recycle, safety and environmental needs of the polysilicon and silane industries

Plastics

While the field of chemical plastic recycling is relatively new, Koch Modular’s extensive experience and hands-on process analysis and development have put us significantly ahead of the curve.

We have worked with many common plastic recycling steps such as Purification, Thermal Decomposition, and Chemical Conversion and have expertise in processes including, but not limited to: Gasification, Pyrolysis, Methanolysis and Chemical Depolymerization.

Others

The extensive list of other chemical compounds with separation, recovery, purification and reaction experience.