Typical Industrial Applications for Separation by Liquid-Liquid Extraction

Koch Modular has the experience and technology to make industrial liquid-liquid extraction processes efficient and cost-effective. We know how to develop extraction processes, how to generate the proper scale-up data, and how to use this data to design and supply extraction columns with process performance guarantees. By offering a broad range of extraction columns (KARR®, SCHEIBEL®, and packed), we can identify the best column for each application and then work with our clients to optimize their process. We have a pilot plant dedicated to the development of extraction processes. We can also provide equipment and services for laboratory, pilot plant, and demonstration plant facilities.

While distillation works on the principle of boiling point difference, liquid-liquid extraction works on the principle of chemical structure difference. This makes extraction ideally suited for separation problems such as those listed below (click on the boxes below to view sample flowsheets).

- Fermentation and Algae Broths

- Acetic Acid Extraction

- Caprolactam Extraction

- Neutralization of Acids/Bases

- Phenol from Wastewater

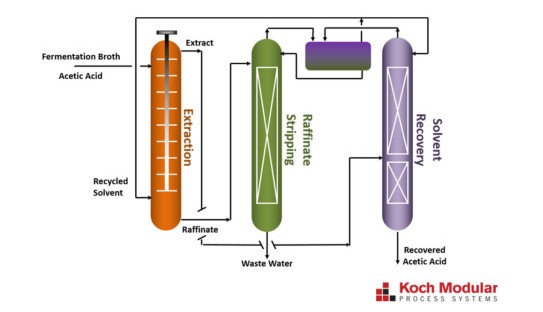

Fermentation and Algae Broths

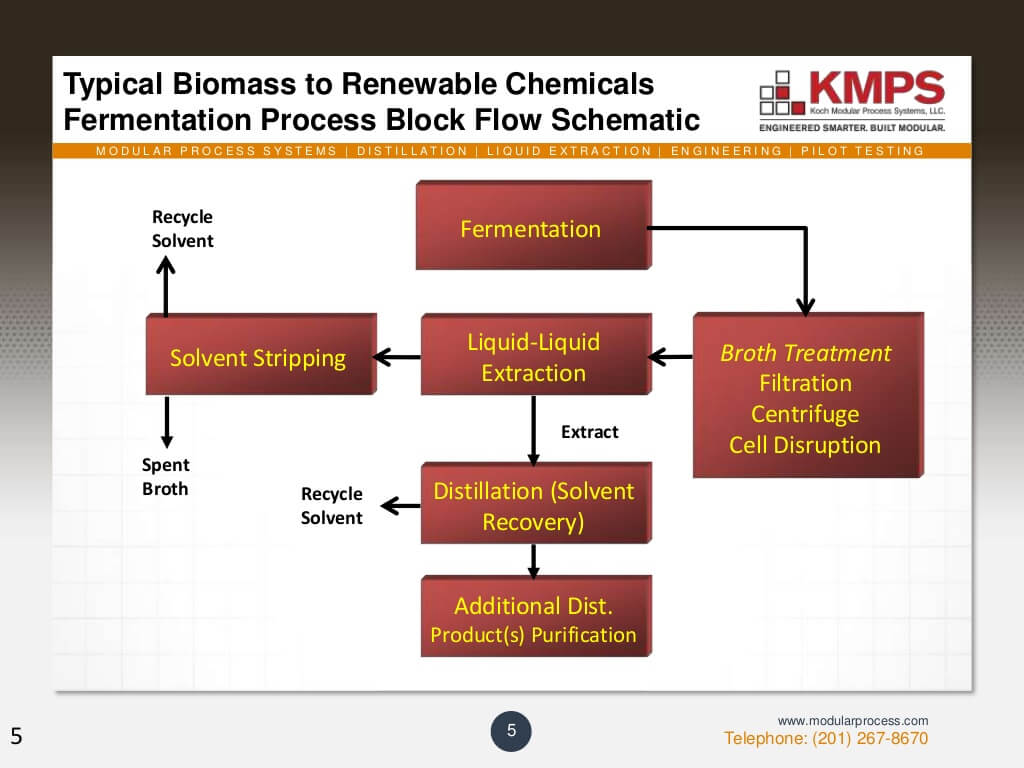

Biofuels and chemicals produced by biological processes such as fermentation and algae often require liquid-liquid extraction (LLE) as the first step in recovery and purification. Many of these chemicals are higher boiling than water or form azeotropes, resulting in high energy requirement for distillation. LLE often offers a process with significantly reduced energy requirement, and as such can provide a cost effective process which has minimal energy utilization, a key factor for effective biofuel technology.

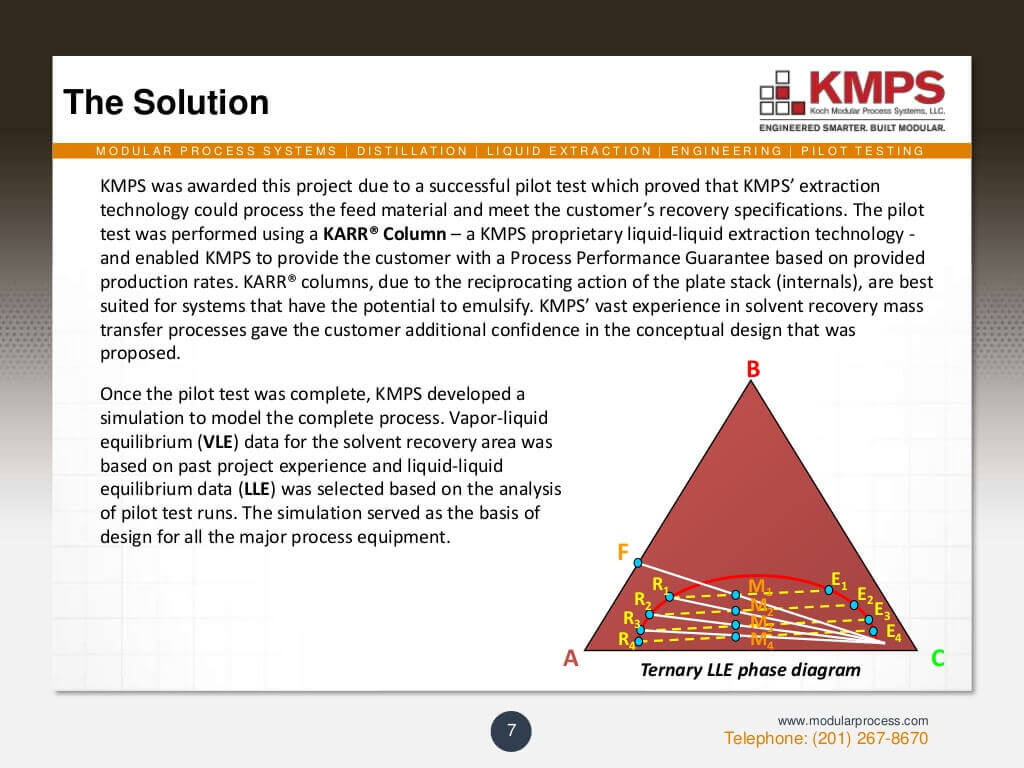

Koch Modular has the experience and technology to make these processes efficient and cost effective. We know how to develop extraction processes, how to generate the proper scale-up data, and how to use this data to design and supply extraction columns with process performance guarantees. By offering a broad range of extraction columns (KARR®, SCHEIBEL®, and packed), we can identify the best column for each application and then work with our client to optimize their process. We have a pilot plant dedicated to the development of extraction processes. We can also provide equipment and services for laboratory, pilot plant, and demonstration plant facilities. As an example, Koch Modular recently partnered with an alternate energy company to demonstrate the commercial scalability of their Second Generation Biofuels Process – see Case Study below

Liquid-Liquid Extraction – Fermentation and Algae Broths

If you are looking for someone to help take your biofuels or biochemicals process from concept to commercialization, we can work with you to:

- Develop the optimal process flow sheet for your particular bio-based fuel or chemical

- Generate laboratory and pilot plant data for scale-up

- Generate sales grade samples of the chemicals using pilot scale equipment

- Design, fabricate and implement demonstration and commercial scale plants

Please visit our main Innovation Partner page for more information on how Koch Modular helped convert novel ideas and processes into practical and efficient operating systems.

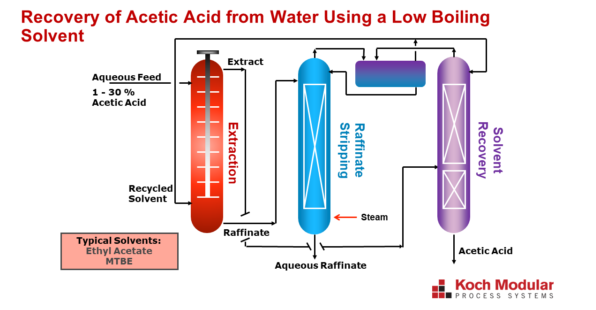

Acetic Acid Extraction

Koch Modular has extensive experience with the recovery and purification of acetic acid (and other carboxylic acids, such as formic acid and valeric acid) from aqueous streams using liquid-liquid extraction (LLE). We have pilot tested, designed, and supplied multiple liquid-liquid extraction columns and systems to the biofuel, biochemical, petrochemical, pharmaceutical, and specialty chemical process industries; applications including processing wastewater and fermentation broths.

If the aqueous feed contains < 30% acetic acid, liquid-liquid extraction is usually a more economical solution than distillation for removal and recovery of acetic acid because the operating costs associated with distilling away the water far outweigh the capital costs of the liquid-liquid extraction process equipment.

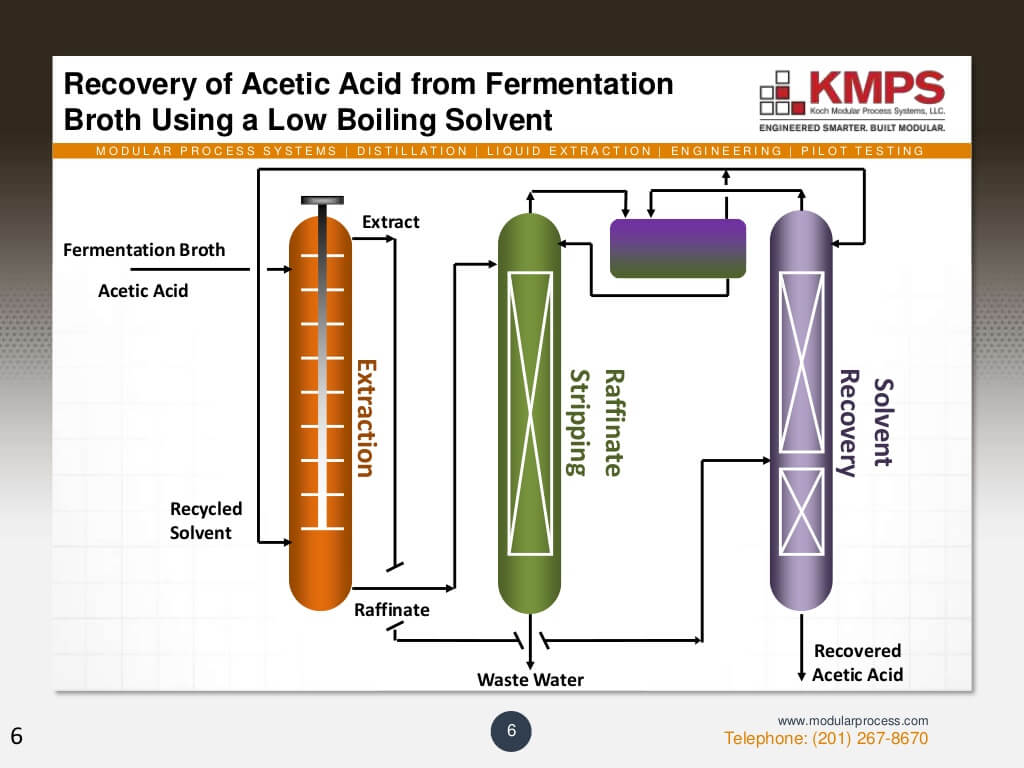

A typical acetic acid extraction system is shown in the Process Flow Diagram below and includes the extraction column, a steam stripper to recover solvent from the aqueous effluent (raffinate), and a distillation column to generate the purified acid while also recovering the solvent for recycling to the extraction column. When designing and supplying this type of extraction system, Koch Modular looks to provide the most economical solution for the entire process by selecting the proper solvent to feed ratio and then optimizing the complete system.

Liquid-Liquid Extraction – Acetic Acid

Typical solvents used for acetic acid recovery via liquid-liquid extraction are ethyl acetate, isopropyl acetate, and MTBE.

Key aspects of Koch Modular’s experience with acetic acid are:

- Developed Liquid-Liquid and Vapor-Liquid equilibrium data when necessary information was unavailable in the literature

- Tested more than 15 different acetic acid aqueous streams in our pilot plant columns

- Designed and supplied more than 10 commercial LLE columns and numerous systems for acetic acid extraction and recovery

- Supplied high efficiency LLE columns which allow minimization of solvent usage and thus the most economical solutions

- Recovered Acetic acid at greater than 99.5% purity

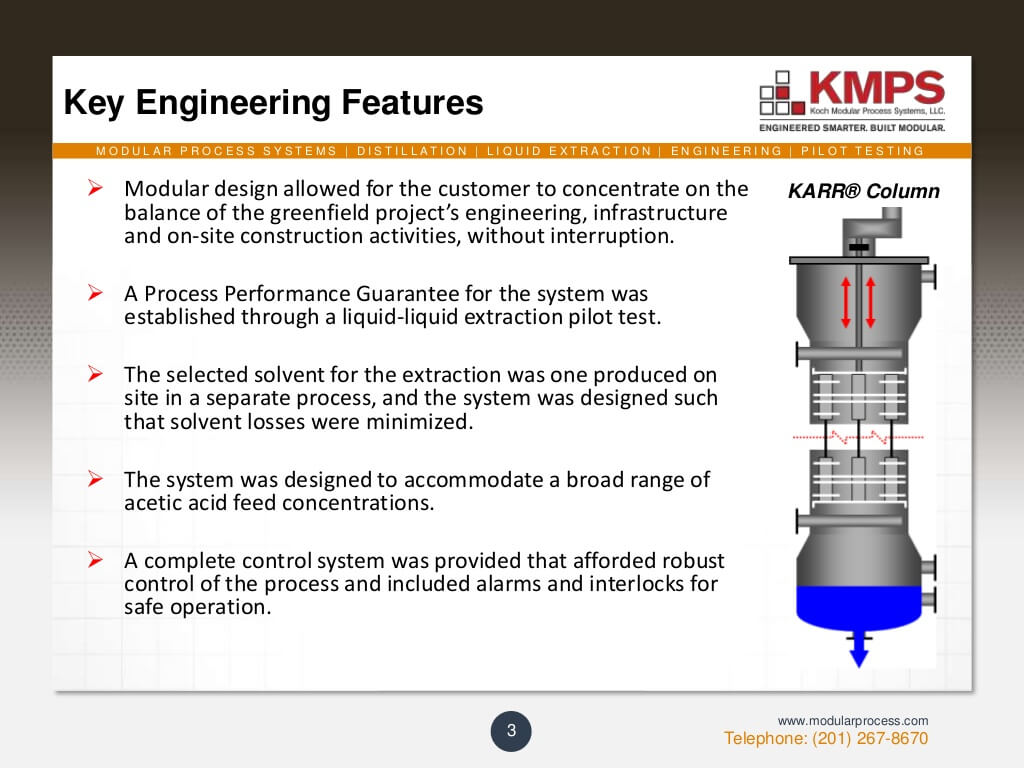

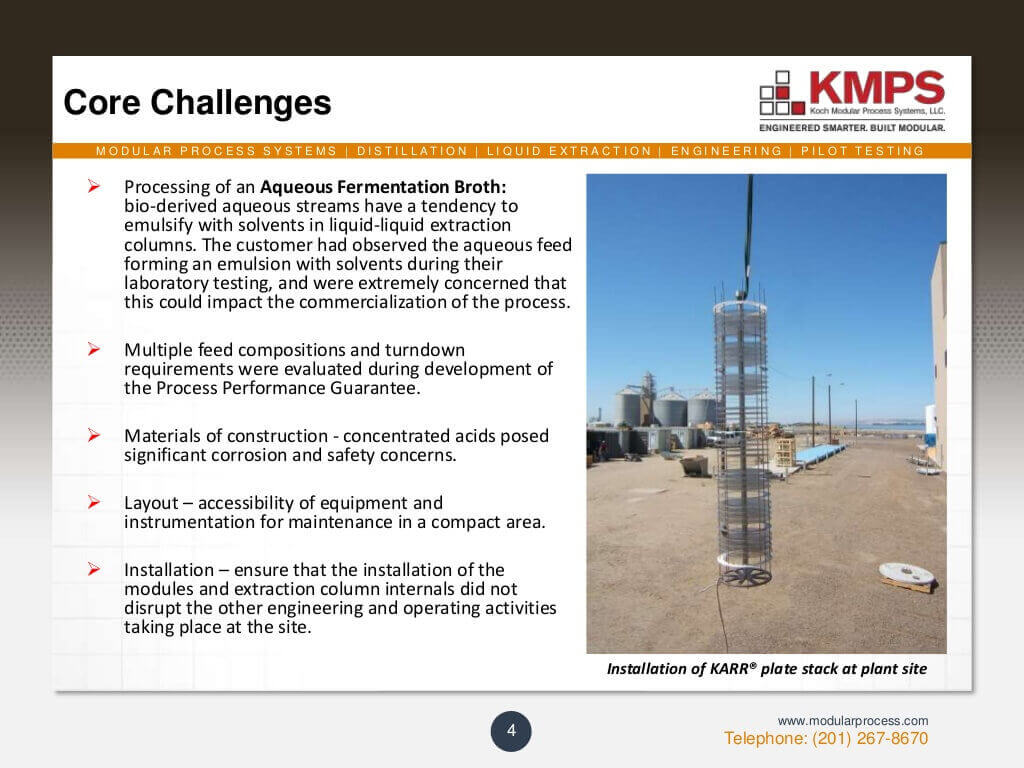

- For fermentation broths where emulsification can be an issue, our KARR® Column is the best industrial solution – see attached photo of KARR® Column used in a demonstration plant for recovery of acetic acid from a fermentation broth.

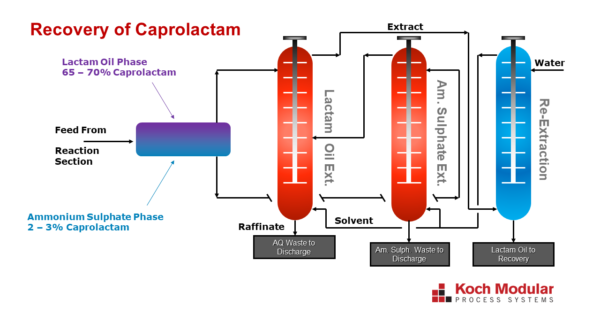

Caprolactam Extraction

Liquid-Liquid Extraction – Caprolactam Extraction

Recovery of products from reactions; such as caprolactam and adiponitrile (for nylon production), acrylic acids and agricultural chemicals.

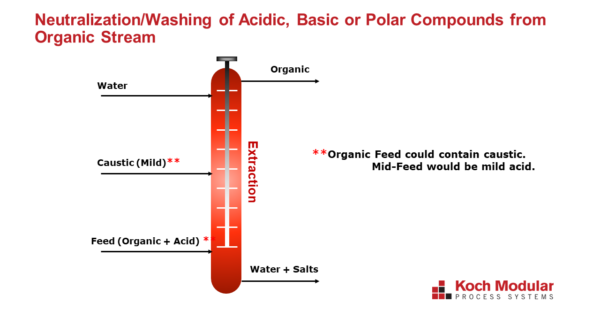

Neutralization of Acids/Bases

Liquid-Liquid Extraction – Neutralization Acids/Bases

Such as acrylates, nitrated organics and chloro-benzene compounds.

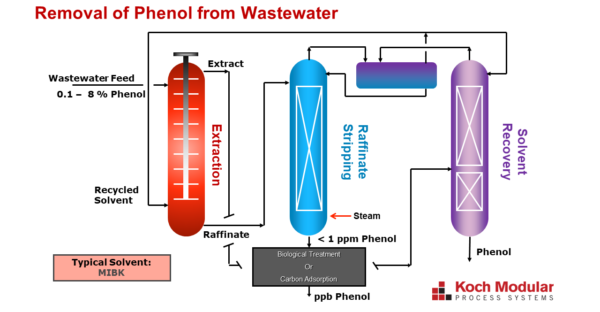

Phenol from Wastewater

Liquid-Liquid Extraction – Phenol from Wastewater

Removal of high boiling organics from wastewater; such as phenol, aniline and nitrated aromatics.

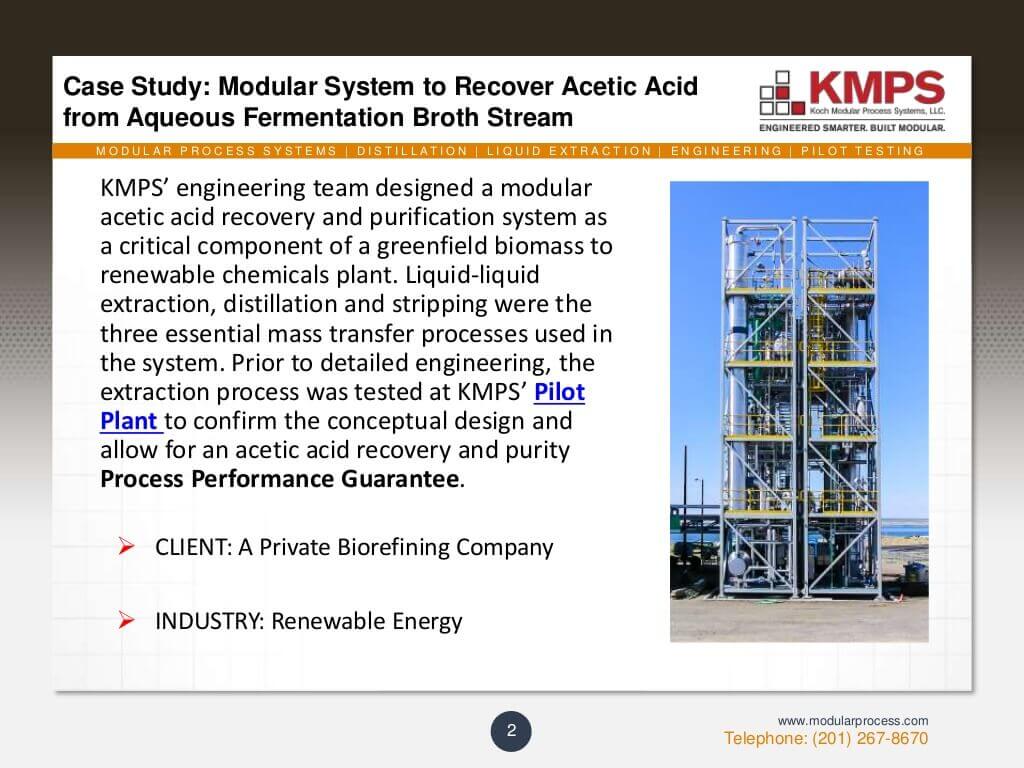

Case Study: Acetic Acid Recovery from Aqueous Fermentation Broth

For more successful case studies by Koch Modular, check out our White Papers and Presentations.

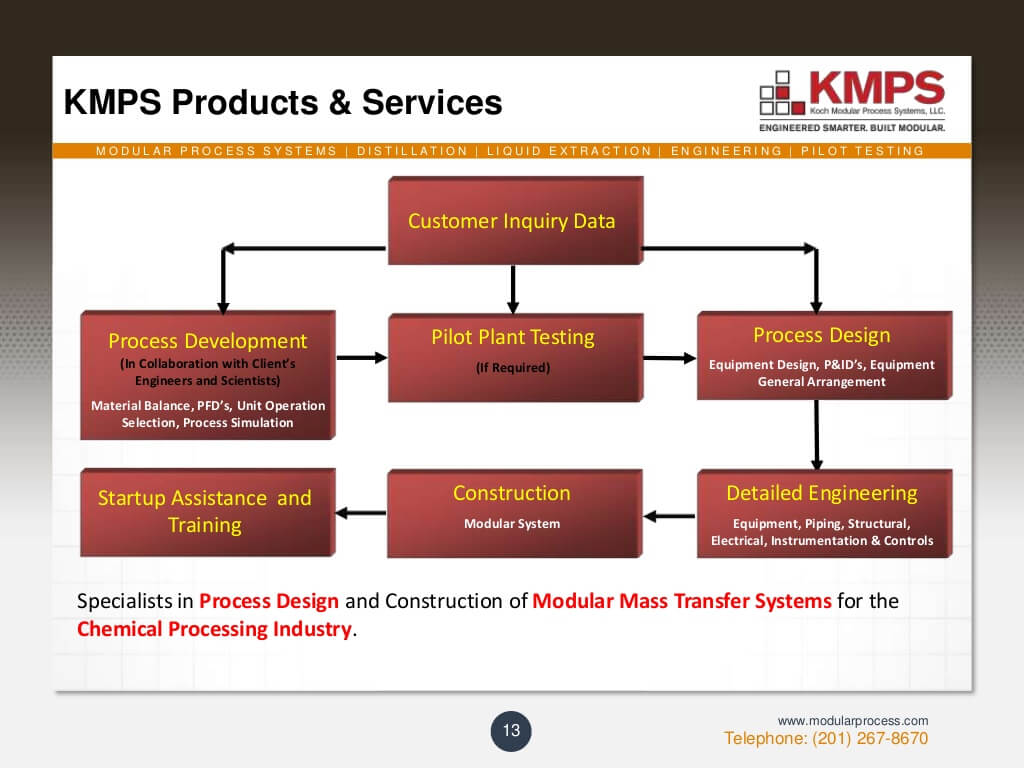

If you are looking for someone to help take your biofuels or biochemicals process from concept to commercialization, we can work with you to:

- Develop the optimal process flow sheet for your particular bio-based fuel or chemical

- Generate laboratory and pilot plant data for scale-up

- Generate sales grade samples of the chemicals using pilot scale equipment

- Design, fabricate and implement demonstration and commercial scale plants