This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home / Liquid-Liquid Extraction / Extraction Column Types

Extraction Column Types: Agitated and Static Columns for Liquid-Liquid Extraction

As part of our liquid-liquid extraction equipment, Koch Modular has a wide range of extractors to choose from, including static and agitated columns. In addition to Koch Modular’s signature KARRⓇ Columns and SCHEIBELⓇ Columns, we also provide rotating disc contactors (RDC), pulsed columns, and special designs for those in need of an agitated column design, as well as sieve trays, random packing, and structured packing (SMVP) static columns.

KARRⓇ Column – Liquid Liquid Extraction Equipment

Characteristics

- Highest capacity: 30-60 M3/M2-hr

- Good efficiency

- Good turndown capability (25%)

- Uniform shear mixing

- Best suited for systems that emulsify

SCHEIBELⓇ Column – Liquid Liquid Extraction Equipment

Characteristics

- Reasonable capacity: 15-25 M3/M2-hr

- High efficiency due to internal baffling

- Good turndown capability (25%)

- Best suited when many stages are required

- Not recommended for highly fouling systems or systems that tend to emulsify

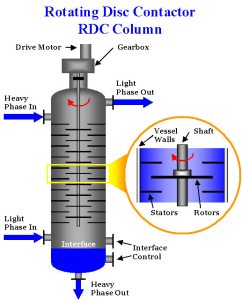

Rotating Disc Contactor (RDC) Columns – Agitated Column Design

Characteristics

- Reasonable capacity: 20-30 M3/M2-hr

- Limited efficiency due to axial backmixing

- Suitable for viscous materials

- Suitable for fouling materials

- Sensitive to emulsions due to high shear mixing

- Reasonable turndown (40%)

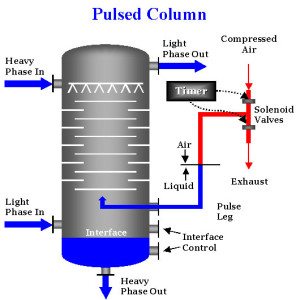

Pulsed Column

Characteristics

- Reasonable capacity: 20-30 M3/M2-hr

- Best suited for nuclear applications due to lack of seal

- Suited for corrosive applications when constructed out of non-metals

- Limited stages due to backmixing

- Limited diameter/height due to pulse energy required

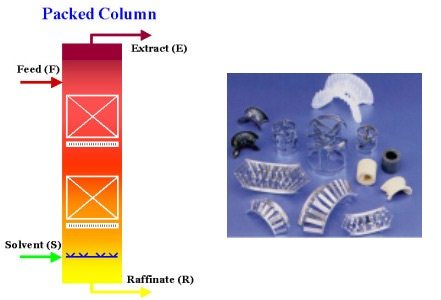

Sieve Tray

Characteristics

- High capacity: 20-30 M3/M2

- Poor efficiency due to backmixing and wetting

- Limited turndown flexibility

- Affected by changes in wetting characteristics

- Limited as to which phase can be dispersed

Packed – Random

Characteristics

- High capacity: 40-80 M3/M2-hr

- Poor efficiency due to backmixing and wetting

- Limited turndown flexibility

- Affected by changes in wetting characteristics

- Limited as to which phase can be dispersed

Packed – Structured

Characteristics

- High capacity: 30-50 M3/M2-hr

- Good efficiency due to minimum backmixing

- Multiple interfaces can be a problem

- Limited turndown flexibility

- Affected by changes in wetting characteristics

- Limited as to which phase can be dispersed

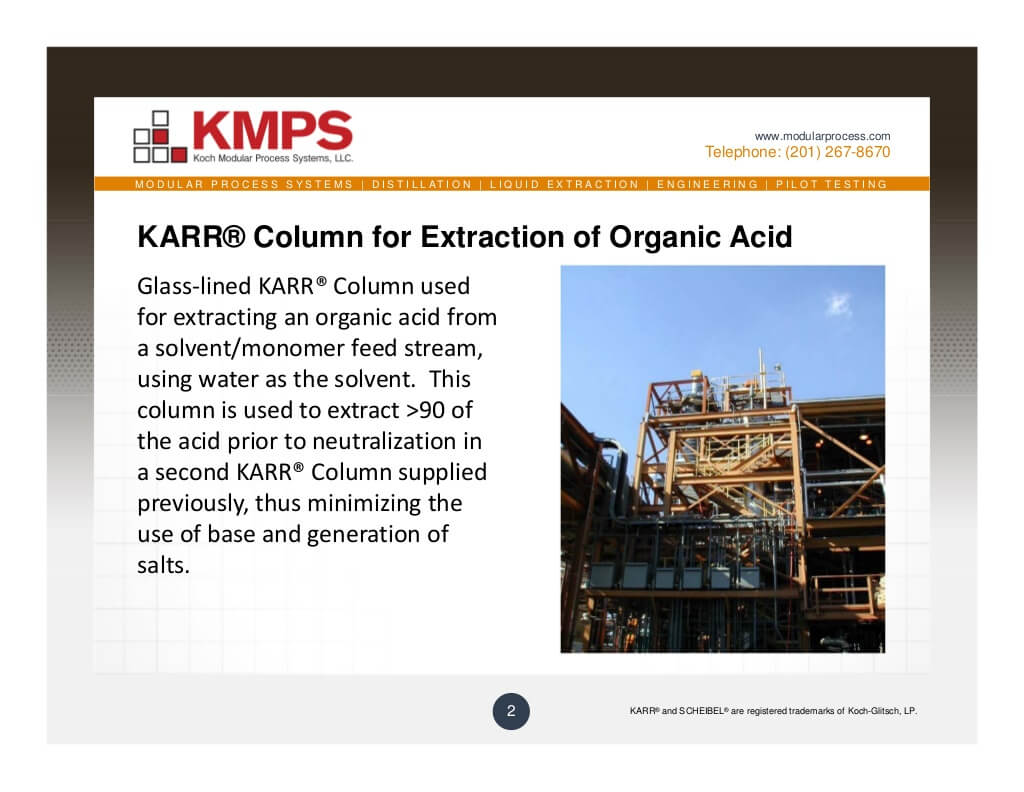

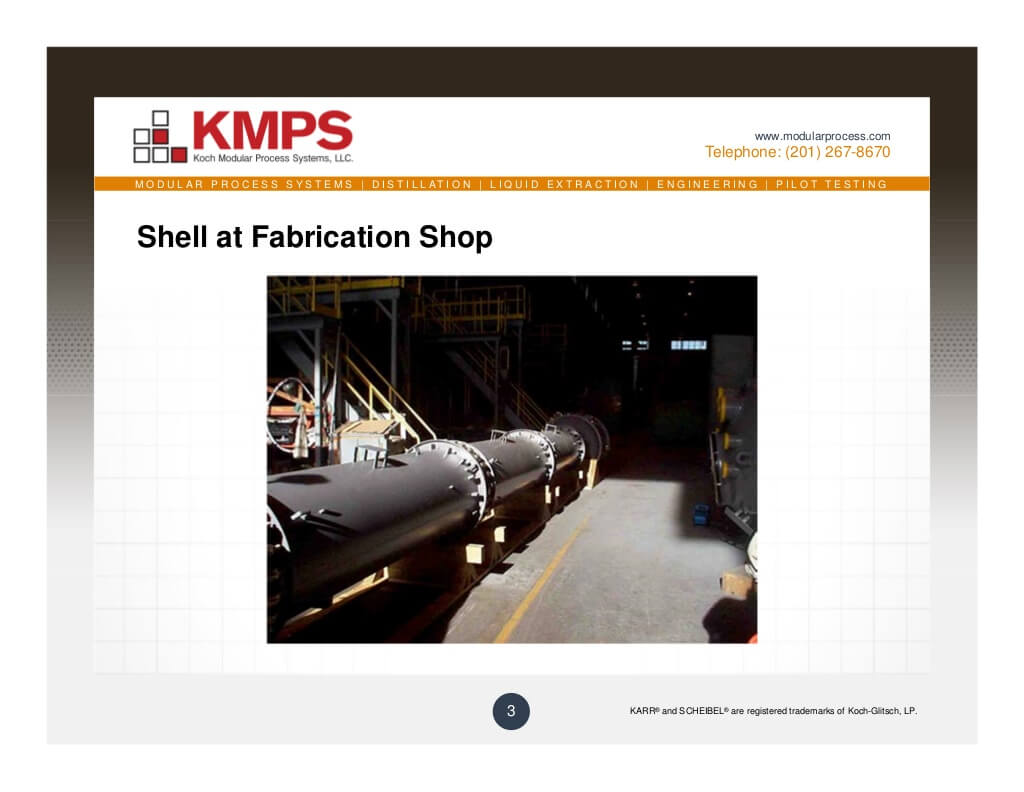

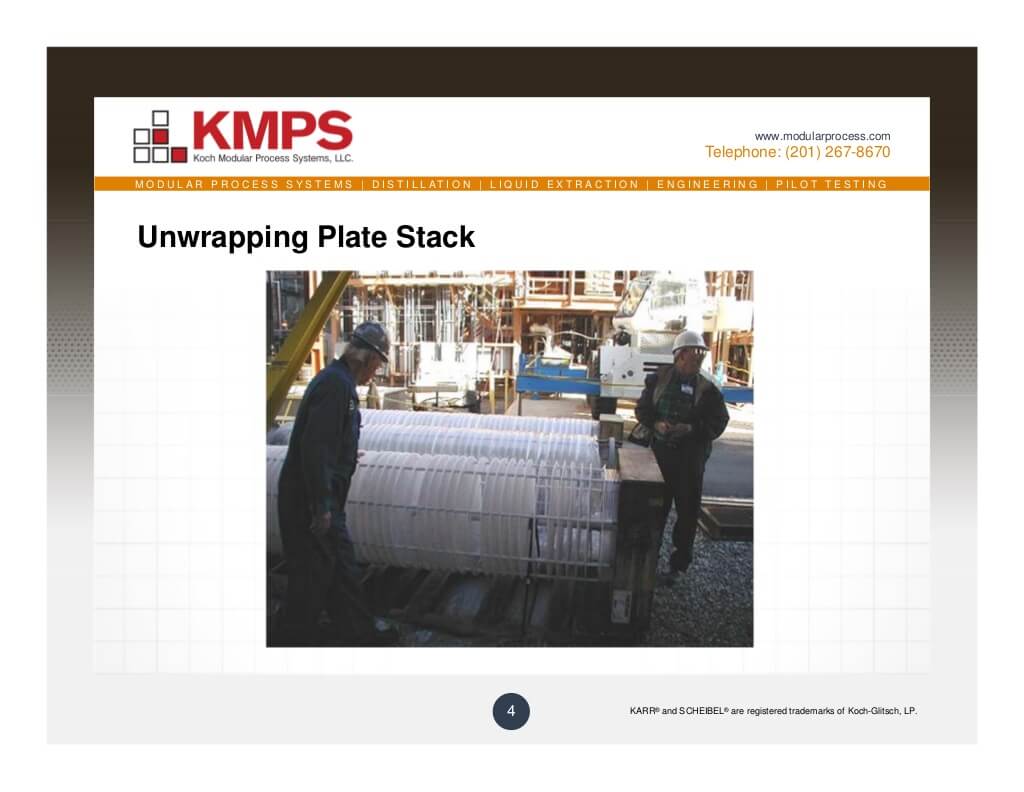

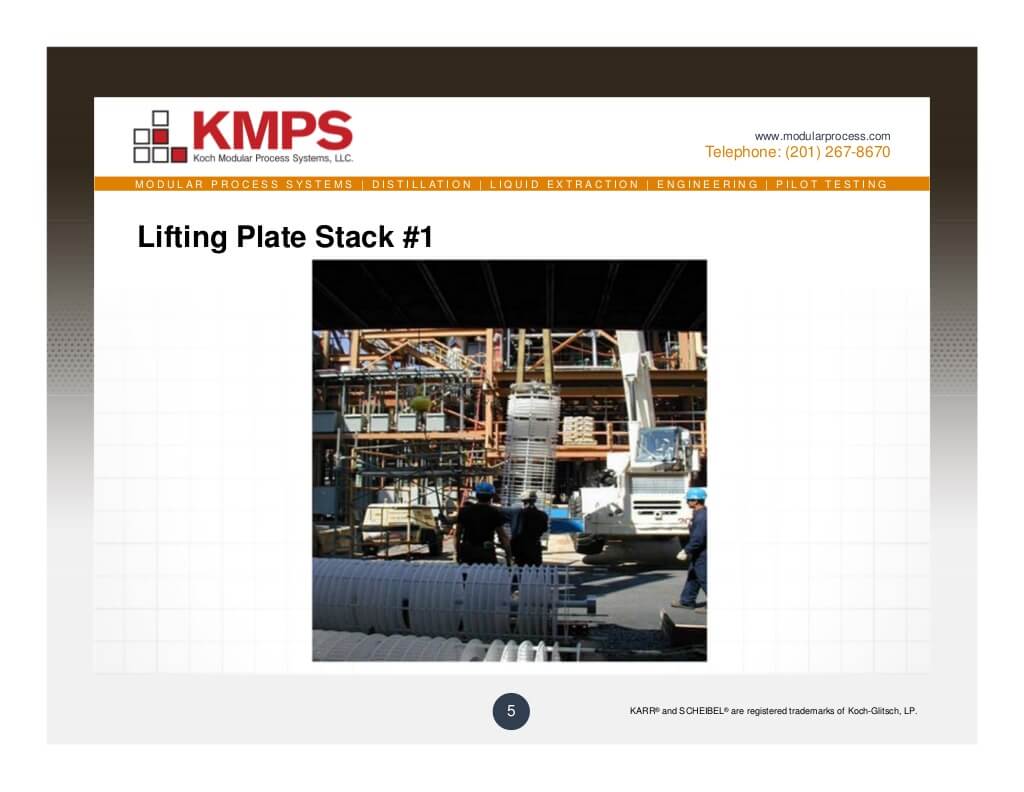

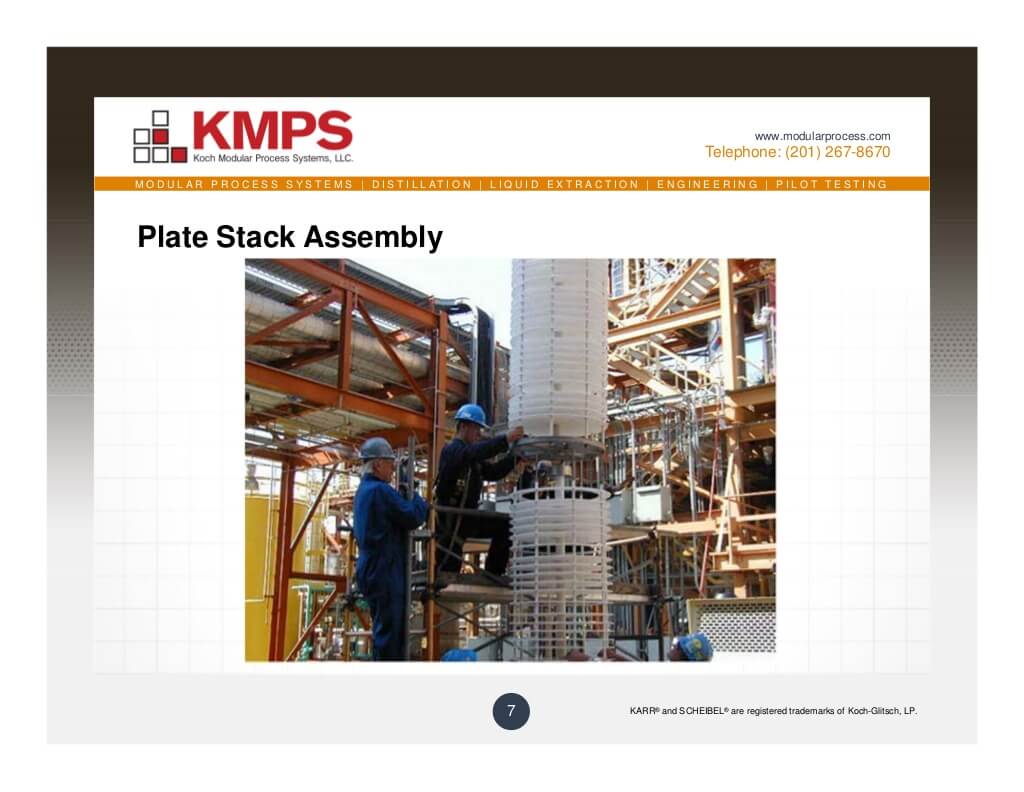

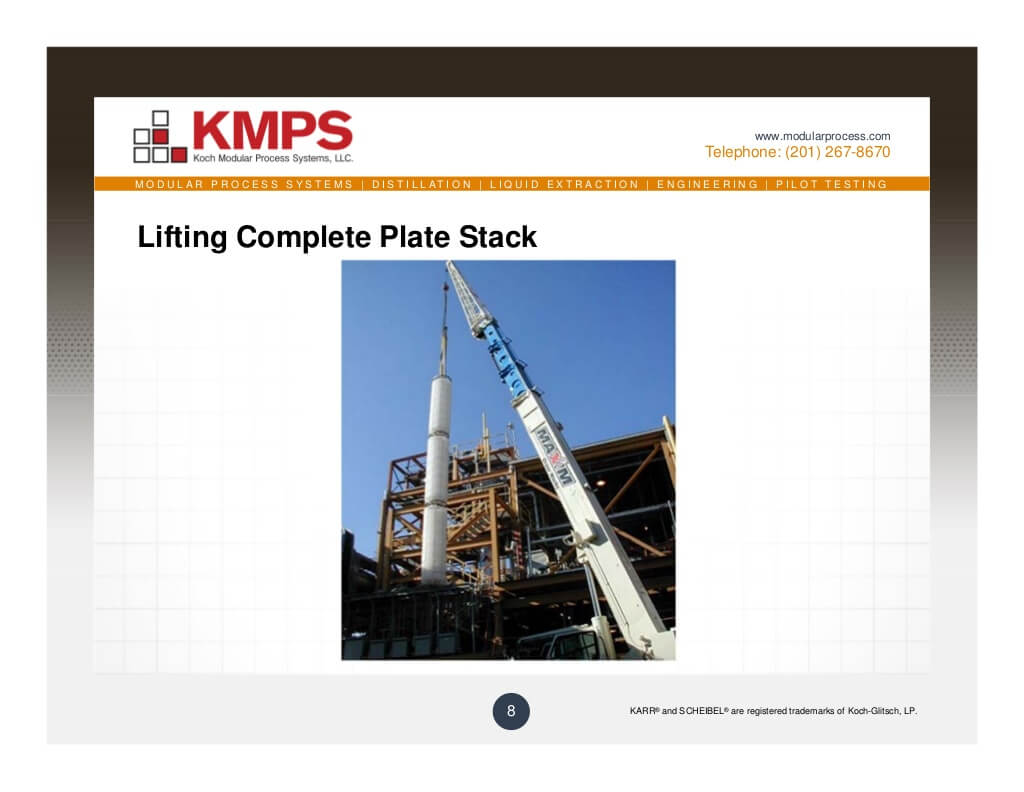

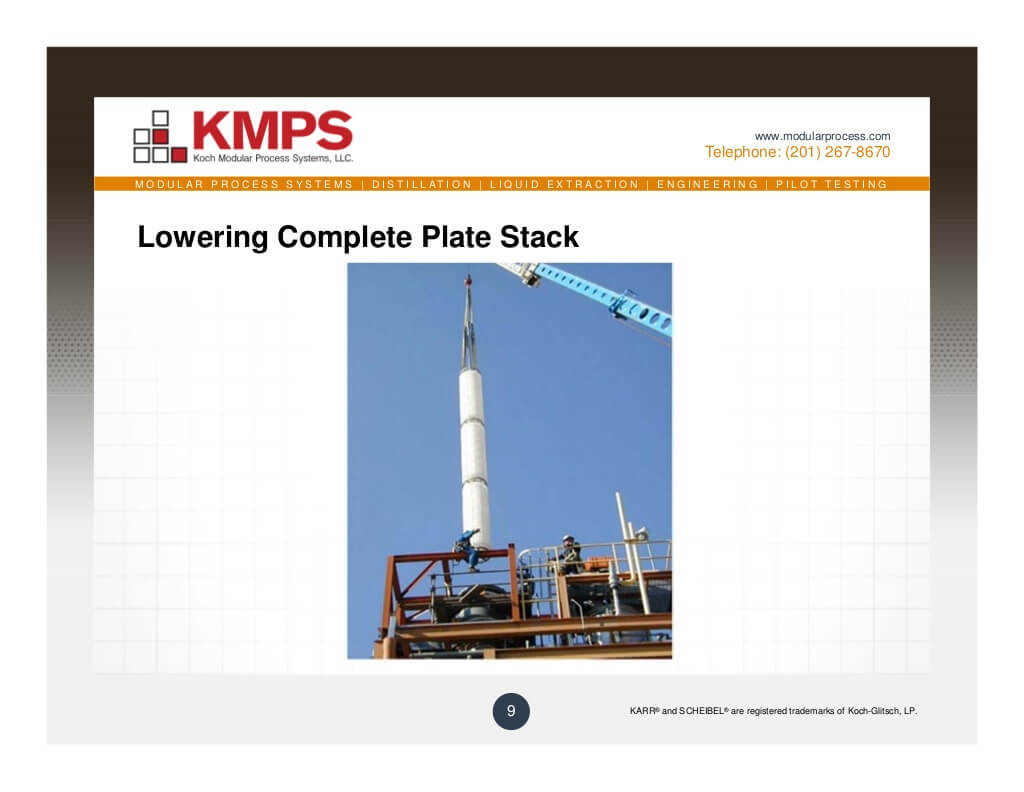

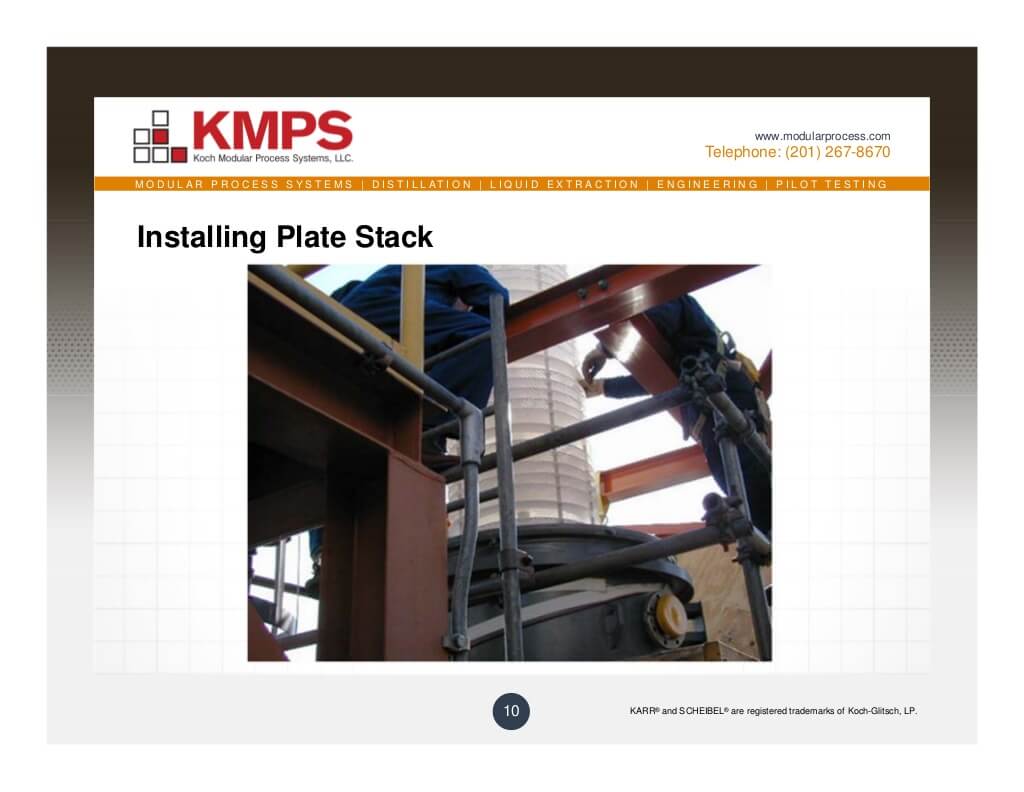

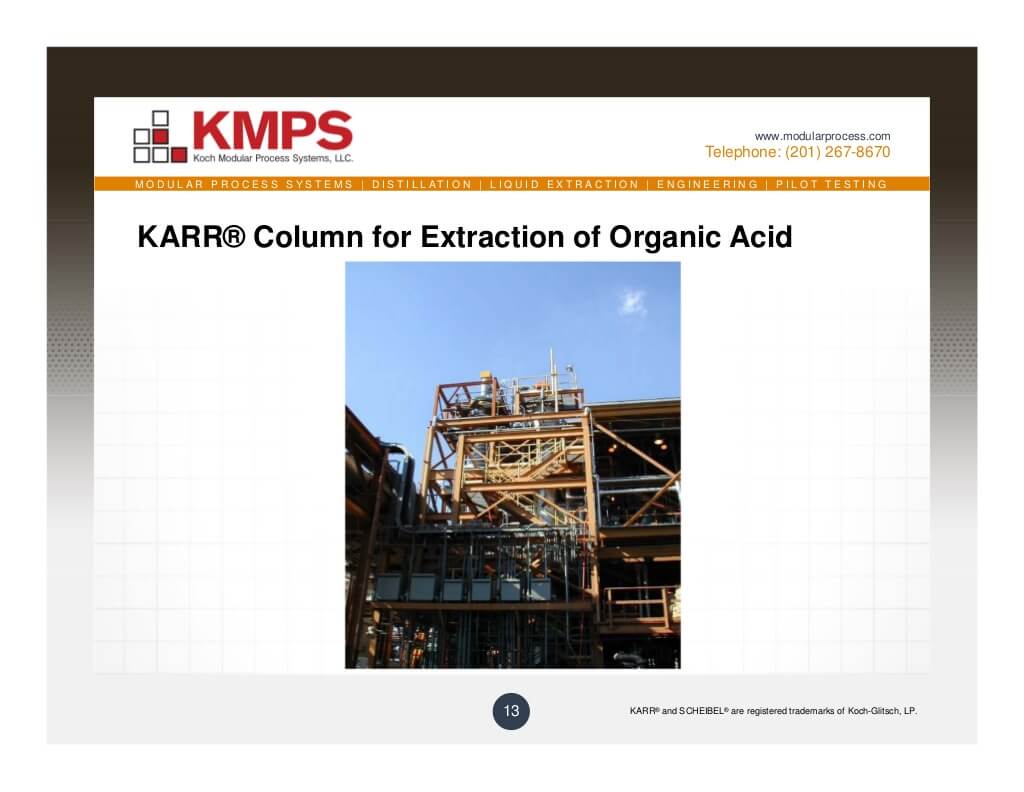

Explore the assembly of a KARR® Extraction Column, which is used to effectively extract organic acid from a feed stream.

For more successful case studies by Koch Modular, check out our White Papers and Presentations.