Liquid-Liquid Extraction: Generating Equilibrium Data

July 2019

/Category:Liquid-Liquid Extraction

Liquid-liquid extraction (LLE) utilizes differences in the relative solubilities of compounds in two immiscible liquids, typically one aqueous and one organic. The feed containing the solute to be extracted is contacted with the solvent, thereby effecting a transfer of the solute from the feed into the solvent. In an extraction column, the heavy phase is added to the top of the column and the light phase to the bottom. The two immiscible phases flow counter-currently, resulting in the solvent extract phase containing the solute and the raffinate, which is the feed phase after removal of the solute. Downstream processing can then recover the solvent for reuse.

Understanding The Use of Shake Tests

So, where to start? Shake tests provide equilibrium data for the two immiscible phases. Solvent-to-feed ratio and number of stages the process will ultimately require can be gleaned using an advance on the old handheld separation funnel.

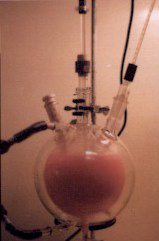

The current shake test method uses a jacketed, round-bottom flask with a standard half-moon impellor and a bottom outlet. The contents are brought to temperature with slow mixing. At temperature, the agitation speed is increased in excess of 1,000 rpm for exactly two minutes, agitation shut off, and the phases allowed to separate, be decanted and then analyzed. More mixing time may be required with very viscous liquids. If the liquids tend to form an emulsion, the agitation speed is slowed down.

How is Equilibrium Data Collected?

After the first mix-decant sequence, the raffinate is returned to the flask and mixed with fresh solvent at the projected solvent to feed (S/F) ratio. The sequence is repeated until the desired solute concentration is reached (usually 4-6x). Our extraction experts will note the sharpness of the interface between the phases and how quickly reached, signs of emulsification or precipitates at the interface, etc. All this data is captured in a log sheet by our shake test operator and provided to you in a report. The report will recommend the type of LLE column best suited for your separation.

Shake test data can be generated in as little as a few days providing critical information for scale up and more accurate pilot plant testing at the get-go. For more detailed information, check out our article in Chemical Engineering from October 2018.