Carbon Dioxide (CO2) Removal

Chemical Engineering, august 2017

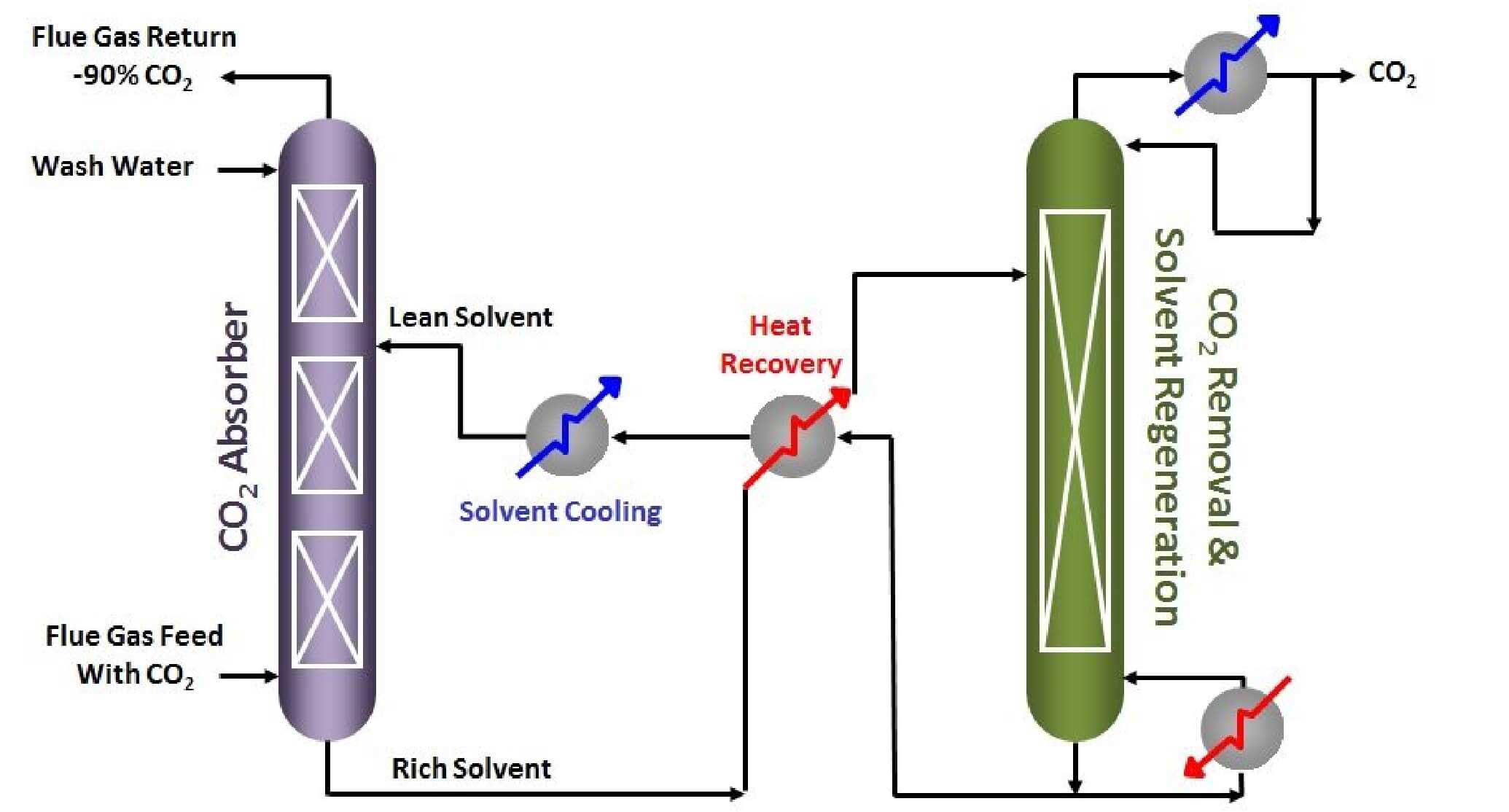

Despite cost hurdles, CO2-capture technologies continue to advance, driven by the critical role of CO2 capture in achieving emissions-reduction goals

Among the possible strategies for addressing climate change risks are CO2-removal approaches, including the capture of CO2 from large emitters, such as power plants and industrial facilities, and also the capture of CO2 from ambient air. These technologies have been explored for some time, and commercialized in some cases, but have yet to be deployed widely, largely because of cost issues. Read More…