Koch Modular has over 40 years experience designing and constructing modular process systems for the Biodiesel Industry. We have successfully supplied numerous recovery and purification systems for the following applications: product purification, methanol recovery and waste water stripping.

Koch Modular recovery and purification systems are modularly constructed, complete with all the equipment and associated process and utility piping, valves, instrumentation and controls installed in structural steel frames. These systems are provided on a lump sum, fixed price basis and fabricated in a controlled off-site environment, resulting in benefits including reduced project schedule, lower total installed cost and minimization of plant site safety risks. All systems are provided with materials and workmanship and process performance warranties.

Biodiesel Services

- Biodiesel Purification

- Glycerin Separation

- Pilot Plant Testing

- Methyl Ester Purification

- Biofuel Refining

- Methanol Scrubbing

- Methanol Recovery

Biodiesel: Process Applications

Koch Modular’s expertise in chemical process design, particularly the design of deep vacuum distillation systems processing thermally sensitive products has made us a leader in the Biodiesel Purification Industry. Our expertise includes the development of process simulation models, design of low pressure drop heat exchangers and distillation column internals, selection of vacuum systems, process control strategies and the detailed design and construction of fully integrated modular purification and recovery systems.

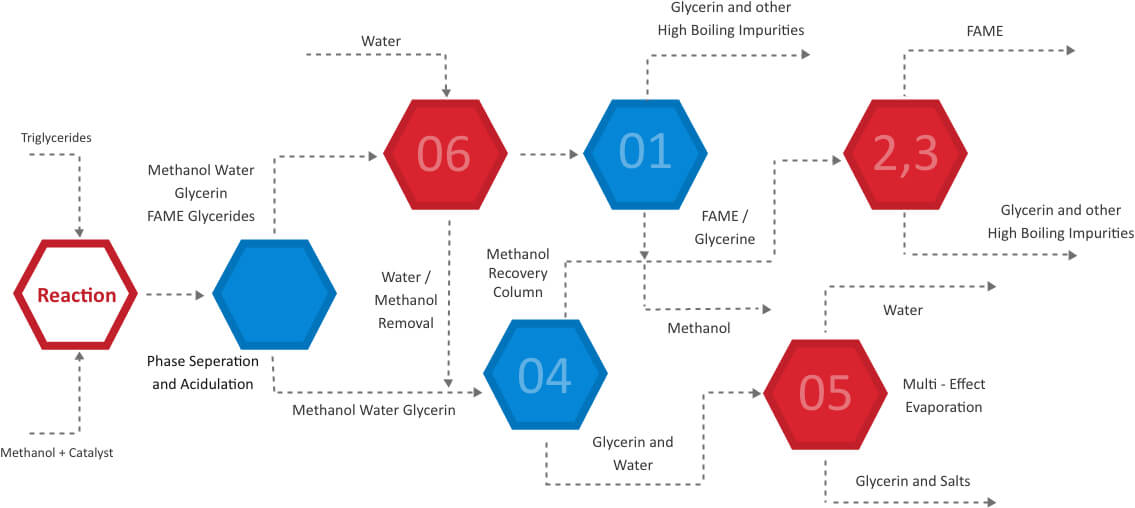

Koch Modular has performed extensive proof of concept pilot testing. These tests, performed at our Houston, Texas Pilot Plant development facility, are based upon actual feedstocks provided by our clients. Please refer to the following Process Flow Diagram summarizing Koch Modular’s areas of biodiesel expertise:

Lights Removal (1)

- Deep vacuum operation which maintains the product’s stability

- Satisfies the ASTM B100 specification for Methanol, Water, and Glycerin

High Purity Methyl Ester Column(2)

- Deep vacuum operation which maintains the product’s stability

- Water-white product quality

- Ultra-low glyceride content

- Reduced Water and Methanol content

Refining Of Methyl Esters(3)

- Koch Modular has developed technology to refine individual Methyl Esters

Methanol Recovery

- Continuous operation

- > 99.8 wt% purity

- > 99.8 wt% recovery

- Duplex/Super Duplex Stainless Steel MOC

Multi-Effect Evaporation To Concentrate Glycerin(5)

- Double or Triple effect evaporation

- Substantially reduces energy consumption

- > 85 wt% Glycerin purity

- Duplex/Super Duplex Stainless Steel MOC

- Koch Modular has also developed the technology to produce technical grade glycerin

Water / Methanol Removal(6)

- Can be accomplished via evaporation or water wash through Liquid-Liquid Extraction

Fill out a project inquiry form for more information on the services we can provide your company.