Tom Schafer Talks Benzene Stripping: Efficiency, Compliance & Innovation

February 2026

/Category:Wastewater

With nearly five decades of expertise spanning process design, operations management, and technology development, Tom Schafer, Co-founder and Vice President of Koch Modular, brings unmatched insight to the field of chemical engineering. Renowned for his deep understanding of distillation, heat transfer, fluid flow, and process control, Tom has been pivotal in advancing separation technologies. In this discussion, Tom reflects on the evolving role of benzene stripping systems—not only as a compliance mechanism, but as a strategic lever for improving operational efficiency and advancing sustainable practices across the chemical industry.

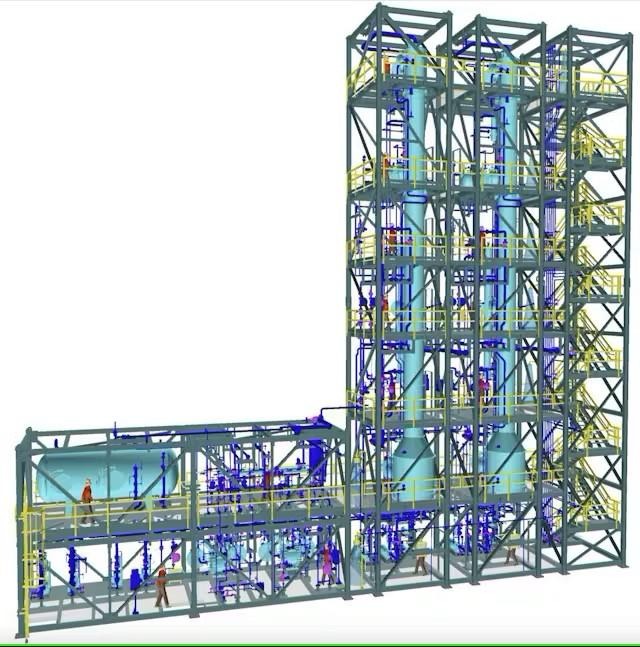

A 3D model of two identical benzene stripping systems.

Q: What prompted the increased focus on benzene removal in petrochemical plants?

A: The EPA issued an enforcement alert in February 2024, warning that chemical plants releasing carcinogens like benzene could face substantial penalties. This has led petrochemical plants to focus on reducing environmental pollutants to comply with regulations and minimize health risks to surrounding communities.

Q: How does the benzene stripping system address regulatory compliance?

A: Effective benzene stripping systems are designed to meet stringent EPA regulations by reducing benzene concentrations in wastewater to levels well below the allowable limits. These systems ensure continuous operation, energy efficiency, and minimal maintenance, making them a reliable solution for compliance.

Q: Why is steam stripping an effective method for benzene removal?

A: Benzene has a lower boiling point and low solubility in water. This allows steam to volatilize benzene efficiently, removing it from wastewater while achieving ultra-low concentrations, often as low as five parts per billion (ppb).

Q: What key design features should be considered for benzene stripping systems?

A: Designing for long-term performance in benzene stripping requires more than meeting baseline specifications—it demands a systems-level approach to reliability, efficiency, and adaptability. Systems should be engineered to mitigate common operational challenges, using fouling-resistant fixed-valve trays to prevent solids from building up, ensuring smooth operation. Spiral plate heat exchangers should be incorporated to improve energy efficiency and reduce fouling risks. Since durability is key, it's common for companies to rely on corrosion-resistant materials like Duplex Alloy 2205 to handle aggressive environments. Many organizations are increasingly adopting modular design frameworks to streamline installation and support scalable growth, allowing process systems to adapt efficiently as operational needs evolve.

Q: Can you explain the implementation of a successful benzene stripping system?

A: In one application, an ethylene facility faced stringent environmental regulations requiring deep benzene removal from its wastewater stream. To meet these demands, we engineered a modular steam stripping system capable of treating flow rates up to 200 gallons per minute while consistently achieving benzene concentrations below 0.1 ppm. The solution not only ensured regulatory compliance but also delivered high operational efficiency with minimal maintenance—demonstrating the value of targeted design in high-throughput, compliance-critical environments.

Q: What challenges do benzene stripping systems face, and how does Koch Modular address them?

A: One of the biggest challenges in benzene stripping is fouling from polymer buildup, which can seriously impact system performance. On top of that, making sure the materials can withstand corrosive streams and achieving ultra-low benzene concentrations to stay compliant adds another layer of complexity. To be successful, these challenges need to be tackled head-on with advanced separation technologies, optimized tray efficiency, and innovative heat integration strategies, ensuring our systems run smoothly and reliably.

Q: How does the modular approach benefit companies?

A: Built in an off-site fabrication shop, the modular design allows for easier installation, shorter project schedules, and reduced operational downtime. It also enhances operational flexibility and efficiently ensures the system meets specific client needs.

Q: What role do benzene stripping technologies play in sustainability?

A: These technologies contribute to cleaner air and water, reduce health risks in surrounding communities, and help industries operate more sustainably while maintaining regulatory compliance.

A modular process system in transit and delivered horizontally for efficient transport and designed for vertical installation on-site.

Conclusion

Benzene stripping is essential for meeting environmental regulations and ensuring cleaner air and water. Companies need efficient, reliable solutions that help industries stay compliant while optimizing performance. With our advanced technologies and expertise, we make benzene removal more effective, sustainable, and hassle-free.

About the Author

Tom Schafer, Vice President at Koch Modular Systems

Tom Schafer is a chemical engineer with 48 years of experience in process design, operations management, cost estimating, plant layout, and sales and marketing. His specific expertise in equipment design includes distillation, heat transfer, fluid flow, and process control. Schafer earned BS and MS degrees in chemical engineering from Manhattan College.