This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Challenge

Koch Modular was initially approached for their demonstrated optimization expertise in reaction, distillation and filtration unit operations. One of the technical challenges the company faced was determining how to compensate for changing byproduct compositions as a result of evolving feedstock selection, alongside the need to produce a consistent yield of material. They also requested guidance with engineering services, process conceptualization and pilot testing in order to take their revolutionary, small-scale manufacturing to successful full-scale production.

SOLUTION

Koch Modular proposed that the project be split into two phases. The first phase consisted of the front 70% of the process and included technical guidance with all of the front-end detailed engineering along with fabrication based on substantial pilot work that had already been completed. The two phase approach would allow the start-up company to continue down their critical R&D path of the back 30% of their process while at the same time, completing the front-end design and fabrication of their technology.

This six year collaboration between the two companies began by leveraging Koch Modular’s core capabilities in process engineering and pilot testing. From there. Koch Modular developed a suitable process design package. including detailed project estimates, based on a design solution that lowered overall capital costs. Subsequently, during the engineering phase, value engineering efforts further refined the overall design thus delivering a fit-for-purpose modular system.

During the peak of this engagement, Koch Modular’s team managed 9 major equipment fabricators, a structural steel supplier, an assembly shop and numerous smaller vendors in order to remain on track for project completion target.

Koch Modular’s skilled project management team delivered a multi-pronged communication approach through weekly lead project manager and engineering meetings, as well as bi-monthly reviews with senior executives. Additionally, the company’s steering committee was key fully informed on project progress and given an opportunity to review any potential risks early on.

RESULTS

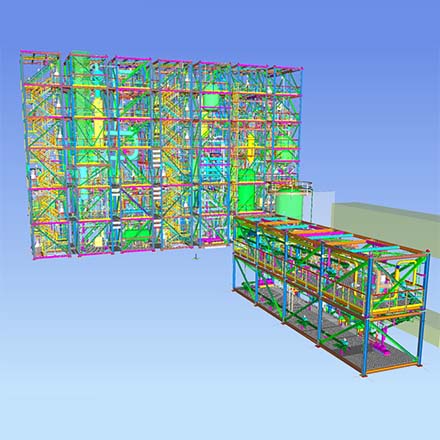

Koch Modular delivered the engineering and construction of the company’s demonstration scale system on time and on budget. Scope included 15 process modules, 2 stair modules and a large stand-alone vessel, complete with all process equipment, process/utility piping, instrumentation, wiring, etc. In addition to supplying the control systems for the Koch Modular process modules, Koch Modular will also include ISBL and OSBL programming for the entire plant.

Since the manufacturing facility was located in Canada, Koch Modular team members were required to interact with the Canadian government in order to remain compliant with any unique requirements. However, Koch Modular was also able to rely on their 15+ year history with fabrication shops within the USA to supply a cost reduction over locally sourced Canadian shops.

The close collaboration between this bio-based plastics company and Koch Modular has resulted in a well-documented, high-quality modular system which satisfied all of the original requirements, and added much more in terms of cost savings and optimization of this distinctive bio-based plastic production process. Koch Modular’s holistic methodology, along with 30+ years of modular and engineering expertise, allowed for the incorporation of production & process efficiencies, ensuring robust and sustainable manufacturing.