- Chemical Engineering

- Mechanical Engineering

- Structural Engineering

- Electrical Engineering

- Controls Engineering

In addition to the engineering of modular systems, Koch Modular provides specific

engineering services to our customers including:

- Equilibrium Data Development and Regression

- Process Feasibility and Optimization Studies

- Process Simulation and Modeling

- Process Design Packages and Front End Engineering Studies

- In-House Pilot Testing

- Detailed Engineering: Chemical Process Equipment, Piping Systems, Structural Support Systems and Electrical Systems

- Process Automation: Design and Programming

- Project Cost Estimating

Chemical Process Engineering – Concept to Commercialization

The Process Design serves as the foundation of any chemical process. Once the throughput rate, product purities and yields are defined, Koch Modular chemical engineers begin the process of design conceptualization, wherein unit operations, system non-ideality, operating efficiency, process safety and capital costs are all considered and evaluated.

With the design concept established, Koch Modular develops an accurate model of the mass transfer system:

- Selection of Equilibrium Data and Activity Coefficients

- Development and Optimization of Chemical Process Simulation

Based upon the Process Simulation standard unit operation, heat and material balance, process flow and instrumentation diagram are created. Reliability, redundancy and flexibility are considered.

- Process Flow Diagrams (PFD’s) with Heat and Material Balance

- Piping & Instrumentation Diagrams (P&ID’s) with line sizing and pipe class specifications, instrumentation locations and process control schemes

Koch Modular Engineers and Designs:

Column Designs including selection of mass transfer internals, hydraulic capacity and mass transfer efficiency.

- Heat Exchanger Thermal Design

- Preliminary Mechanical Drawings for Columns, Vessels and Heat Exchangers

- Pump Hydraulic Calculations and Data Sheets

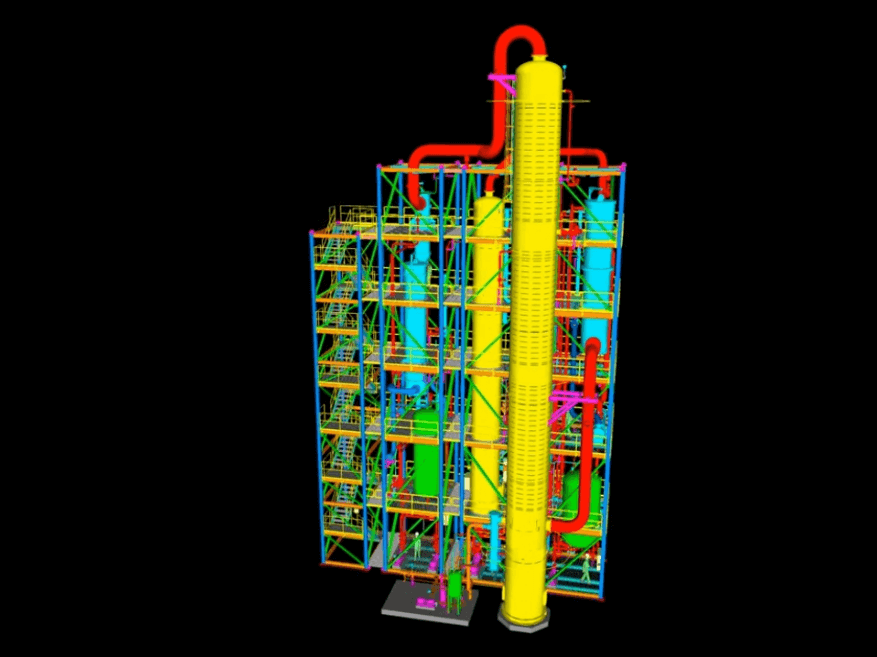

Finally, Koch Modular engineers, together with our experienced piping designers, three-dimensional Equipment General Arrangement drawings incorporating the process’ flow requirements while optimizing accessibility for general operation and maintenance and in consideration of the available plant space.

Typical Process Design Package Documentation

- Process Flow Diagrams (PFD’s)

- Piping & Instrumentation Diagrams (P&ID’s)

- Heat Exchanger thermal designs

- Mechanical drawing lead sheets for columns, vessels, and heat exchangers

- Pump hydraulic calculations and specification sheets

- 3D equipment general arrangement drawings

- Participation in a HAZOP review meeting

- Detailed Project Kick Off List, defining all project scope of supply requirements

- Modular Systems

- Process Design

- Detailed Engineering

- Feasibility Studies

- Pilot Plant Testing

- 3D CAD Modeling

- VLE/LLE Development

- Shell & Tube HX Design

- Project Management

- Process Simulations

- Equipment Design

- Startup & Training

- Distillation Continuous, Batch, Vacuum, Pressure

- Azeotropic Distillation

- Extractive Distillation

- Reactive Distillation

- Pressure Swing Distillation

- Liquid-liquid Extraction

- Stripping

- Absorption

- Reaction Chemistry

- Process Control & Optimization

Chemical Engineers

- Process

- Project

- Control & Automation

- Business Development

Other Engineers

- Mechanical

- Civil / Structural

- Electrical

- Instrumentation

Design Drafting

- Piping Design

- Vessel

- Structural

- Process / P & ID

Other Technical

- Pilot Plant Operations

- Analytical Chemist

- Quality Control

Detailed Engineering Services For Modular Process Systems

Through our extensive detailed engineering procedures, Koch Modular engineers and designers are able to completely and systematically define each component of a modular process system. Equipment, piping, structural steel, instrumentation, electrical and controls systems are all evaluated, optimized and detailed for fabrication.Our senior project managers oversee and orchestrate the overlap and interaction of the multiple engineering disciplines required to successfully and efficiently execute our customer’s projects.

Typical Detailed Engineering Documentation

- Pipe and Valve Specifications

- Piping Drawings: Plan, Elevation, Isometrics with Bill of Materials, 3D Review Model, External Connections Diagram/Coordinates

- Pipe Stress Analysis

- 3-D Model of Entire System in AutoPLANT®

- Equipment: ASME Code Calculations, Fabricated Equipment U-1 Forms, Final Equipment Fabrication Drawings, Pump Data Sheets

- Structural Steel Drawings: Plan, Elevations and Sections, Foundation Loading Diagrams, Lifting and Transport Diagrams

- Electrical Drawings: Conduit Plans, Wiring Diagrams, Electronic Instrument Location Diagrams, Module Lighting Diagram, Terminal Box Layouts and Loop Diagrams

- Instrumentation: ISA Data Sheets, Relieving Capacity Calculations for Pressure Relief Devices and Installation Details

- Controls System: Alarm, Interlock and I/O Lists, Sequence Tables (as required) and Control System Workstation and Licensing Specification

- Lists: Utility List, Power List, Equipment List, Valve List, Instrument List, Pipeline List and Equipment and Piping Paint List

- QA/QC: Project Inspection Plan, Completed Module Assembly Checklist (FAT) and Completed Module Half Loop Test Procedure/Report

- Manuals: Installation, Startup and Shutdown, Maintenance

Detailed Engineering Design Software and Platforms

In addition to the engineering of modular systems, Koch Modular provides specific engineering services to our customers including:

- AutoCAD

- AutoPLANT

- Aspen

- NavisWorks

- AutoPIPE

- COMPRESS

- SolidWorks

- MathCAD

- ALGOR

- STAAD

- Process Control Systems:

PLC & DCS